007TECH

Factory direct sale 1500w 2000w 3000w 6000w metal sheet and metal tube Fiber laser cutting machine

Factory direct sale 1500w 2000w 3000w 6000w metal sheet and metal tube Fiber laser cutting machine

Precio habitual

¥4,370.00 CNY

Precio de oferta

¥4,370.00 CNY

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Product Description

Factory direct sale 1500w 2000w 3000w 6000w metal sheet and metal tube Fiber laser cutting machine

Widely used in kitchen appliances, sheet metal chassis cabinets, mechanical equipment, electronic equipment, lighting hardware, advertising signs, auto parts, fitness equipment and other metal products, sheet metal cutting processing and other industries.

Model |

RF-F3015 |

||||||

Machine size |

4320*2250*1950mm |

||||||

Working area |

1500*3000mm |

||||||

Positioning accuracy |

±0.03mm |

||||||

Repositioning accuracy |

±0.02mm |

||||||

Max. acceleration |

1.5G |

||||||

Laser power |

1kW – 6kW |

||||||

Laser source |

MAX/RAYCUS/IPG |

||||||

Focusing method |

Auto |

||||||

Max. running speed |

140m/min |

||||||

Specification

Raytools auto focus cutting head

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position . The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials.

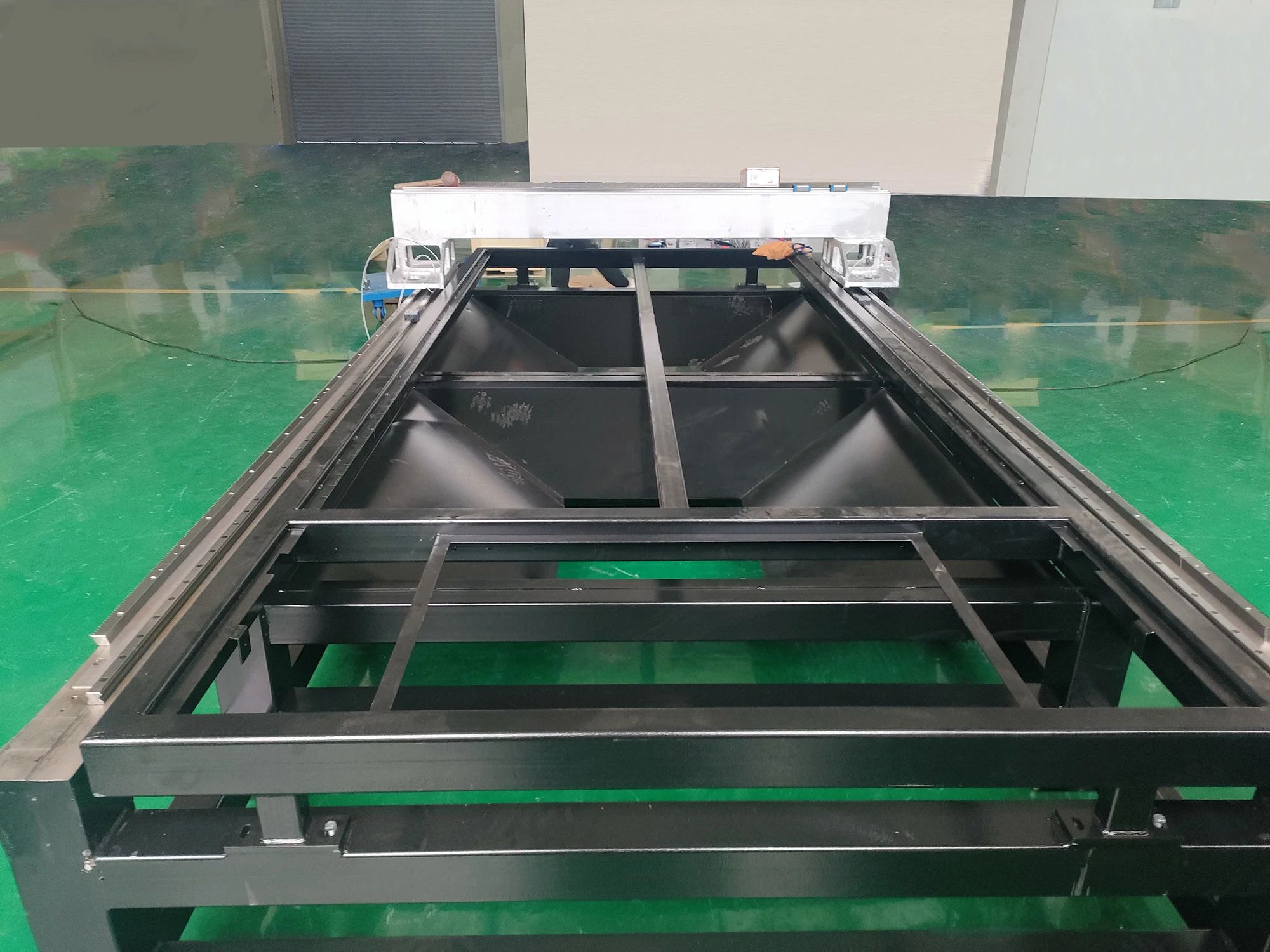

Heavy duty machine body

Weight up to 1.3T, when the machine cutting, it can keep the machine run more stable.

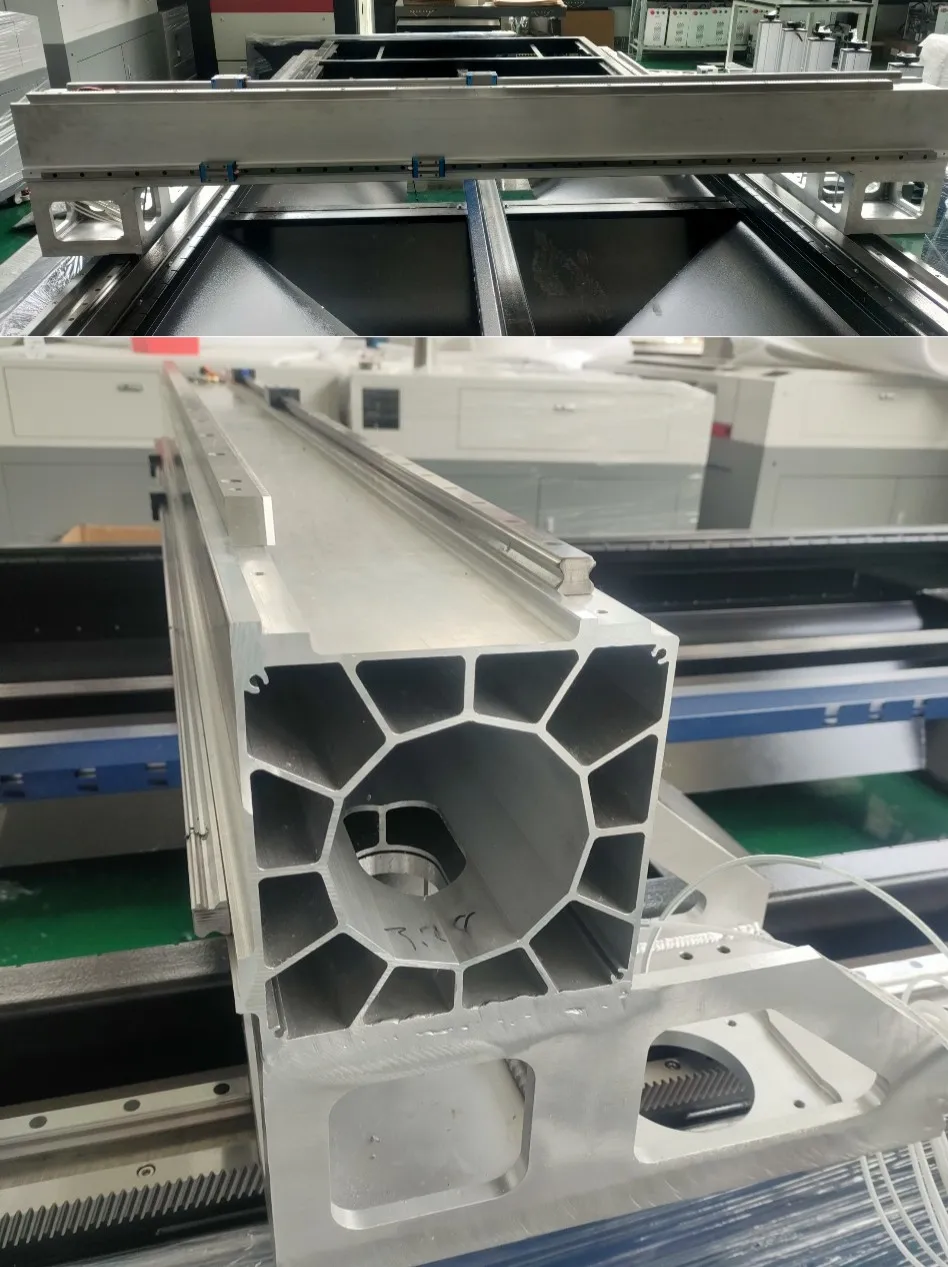

Aluminium alloy Gantry

Resistant to deformation and light in weight, allowing the machine to run faster and cut more accurately

Quality spare parts

Cutting samples

Packing & Delivery

1. Collect all accessories and and spare parts together one by one based on the order list ,and check all parts carefully once more to ensure all parts are included.

2. Our packaging standard:

+thick layer of plastic wrap

+six-sided pearl cotton

+high-strength wooden box

+packing belt and then fix the machine to ensure the safety of the machine during transportation.

3. Stick the shipping mark to ensure the buyer can recognize the right machine easily.

4. Stick the Safety signs can remind transporters to take good care of our equipment during shipping.

2. Our packaging standard:

+thick layer of plastic wrap

+six-sided pearl cotton

+high-strength wooden box

+packing belt and then fix the machine to ensure the safety of the machine during transportation.

3. Stick the shipping mark to ensure the buyer can recognize the right machine easily.

4. Stick the Safety signs can remind transporters to take good care of our equipment during shipping.

Company Profile

FAQ

Q1. How to get the most suitable machines if the buyers are not familiar with them?

You can tell us the material you will engrave or cut. It will be better if you have some pictures or working videos. We’ll

recommend the best model according to our years of experience.

Q2. How about the guarantee and after-sale service?

(1) 2- year warranty for the whole machine.

(2) Technical support by video, manual, pictures or online.

Q3. How long is the delivery time?

It generally takes 14 days if regular models. Customized products takes longer time(we can discuss).

Q4. How will deliver the machines?

The machines can be delivered by sea, air or railway.

Q5. Can you supply door to door service?

For some countries, we can supply door to door services. Please inform your house address and confirm with the sales.

You can tell us the material you will engrave or cut. It will be better if you have some pictures or working videos. We’ll

recommend the best model according to our years of experience.

Q2. How about the guarantee and after-sale service?

(1) 2- year warranty for the whole machine.

(2) Technical support by video, manual, pictures or online.

Q3. How long is the delivery time?

It generally takes 14 days if regular models. Customized products takes longer time(we can discuss).

Q4. How will deliver the machines?

The machines can be delivered by sea, air or railway.

Q5. Can you supply door to door service?

For some countries, we can supply door to door services. Please inform your house address and confirm with the sales.