007TECH

Good price Fiber Laser cutting machine on discount fiber laser cutter machine 1500W 3000W 6000W 12000W

Good price Fiber Laser cutting machine on discount fiber laser cutter machine 1500W 3000W 6000W 12000W

No se pudo cargar la disponibilidad de retiro

Top quality Steel Galvanized Sheet china accurl laser cutting machine

china accurl laser cutting machine Product features:

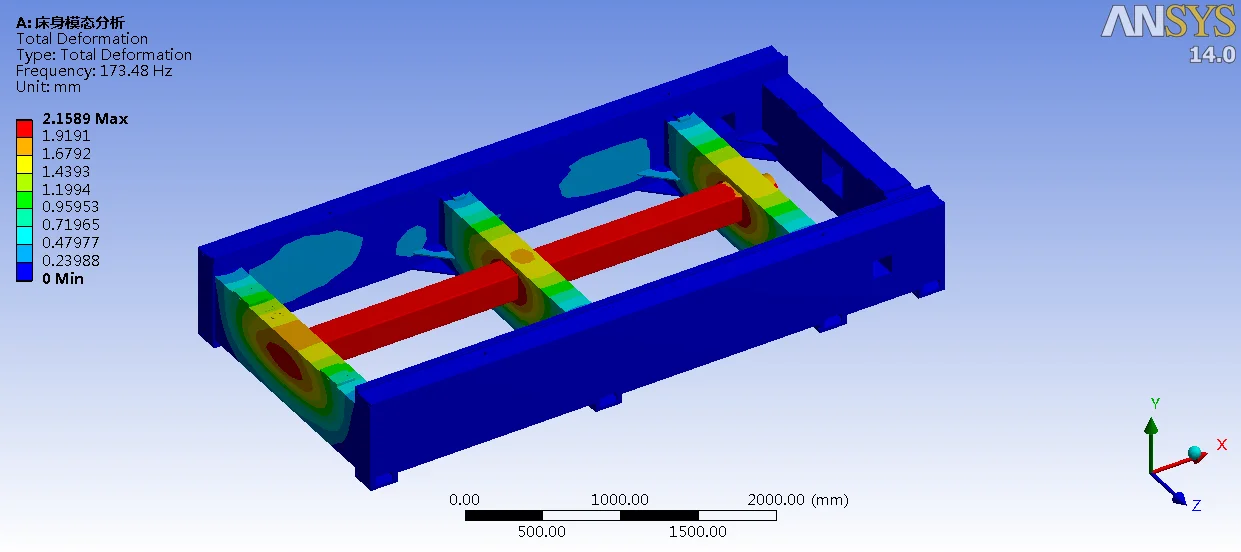

1.Whole Machine welded bed structure,Stable performance,could ensure the stable operation of equipment

2.After 650℃ high temperature heat treatment Machine bed, adopt large Gantry milling accuracy process, ensure machine bed stability and smoothness.

3.Operating system, man-machine interface, easy to operate

4.High quality, high efficiency fiber laser producer. low processing cost and energy conservation and environment protection

5.Servo drive,The structure of the machine tool adopts rack and pinion drive,Ensure equipment high speed , high accuracy, and high reliability

6. Fast delivery 1kw high power CNC metal sheet pipe fiber laser cutting machine , 300W, 500W, 750W, 1000W, 1500W, 2000W, 3000W, 6000W, 8000W fiber laser power available

7. laser cutting machine adopts IPG, N-light, RAYCUS fiber laser source brand available

8. High speed, high accuracy, stable performance, best quality

9. Support Factory Inspection

china accurl laser cutting machine Application

Used for cutting a variety of metal plates, mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, various alloy plate, rare metal and other metal materials.

F3015 fiber laser cutting machine can carry up to 8000W laser power, so cutting some thick plate, it is a very good choice. For example, agricultural machinery, textile machinery, food machinery and construction machinery and other large machinery and equipment manufacturing, usually use high power fiber laser cutting machine for processing.

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum-plating, zinc plate, copper and other metals.

In addition, it possesses high brightness levels and lower reflectivity as well as solid glass panel sturdiness and durability.

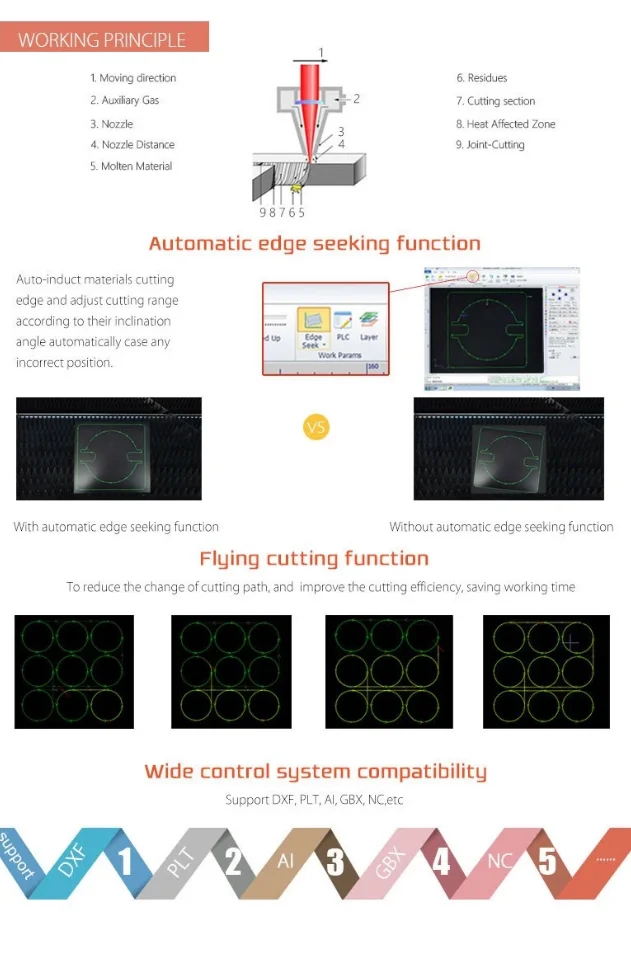

china accurl laser cutting machine Working principle

china accurl laser cutting machine Parameters

|

Model

|

TC-E3015

|

|

Machine power

|

500W/750W/1000W/1500W/2000W/3000W

|

|

Area

|

|

|

Working area

|

3000mm*1500mm

|

|

X-Axis travel

|

3000mm

|

|

Y-Axis travel

|

1500mm

|

|

Z-Axis travel

|

220mm

|

|

Accuracy

|

|

|

X/Y axis positioning accuracy

|

±0.05mm

|

|

X/Y axis repeated positioning accuracy

|

±0.03mm/min

|

|

Speed

|

|

|

Maximum velocity of movement

|

120m/min

|

|

Cutting speed

|

100m/min

|

|

Weight and Measures

|

|

|

Total weight

|

100m/min

|

|

Machine Dimension

|

4800*2600*2100mm

|

|

Transmission Precise pinion and rack

|

dual-drive transmitting

|

Advantages

|

|

Heavy duty plate welding lath bed. The lath bed is welded with a 12mm thick carbon structural steel misaligned honeycomb structure, machined after stress relief annealing, and then subjected to vibration aging and natural aging treatment, so that the stress of welding and machining can be completely eliminated,and can guarantee the lath bed Excellent rigidity and high precision, can maintain normal use for 20 years without deformation.

|

|

|

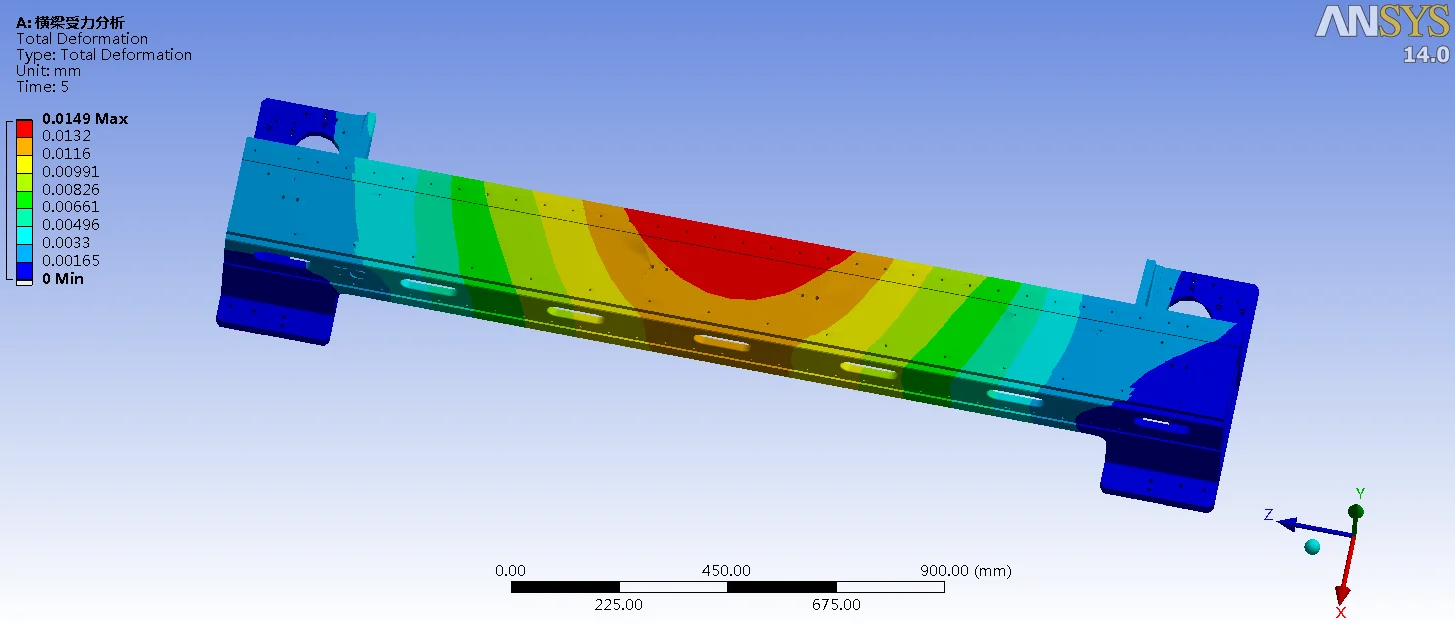

Cast aluminum beam Adopt cast aluminum integrated beam is finished by artificial aging and solution treatment, and the beam rigidity, surface quality and integrity are excellent. It has good dynamic performance and is convenient for high-speed cutting. |

|

Key components The key components are imported from abroad, such as: Yaskawa (Panasonic / Fuji) private service motor, MOTOVARIO (Xinbao) reducer, HIWIN (PMI / ABBA) guide rail, YYC (APEX) rack, etc.IPG and Raycus fiber laser source are available. 3.4 Machine design and modeling (1) Adopting gantry type double-drive structure, imported high-precision reducer, rack and pinion and linear guide rail, the transmission is stable, the speed is fast, and the positioning precision is high. (2) The whole machine adopts split design, the electric control cabinet is independent of the cutting equipment, which can effectively prevent the heat generated during cutting from being transmitted to the electric control cabinet, and is more convenient for maintaining electrical components. (3) Increase the dust removal function of the partition, and at the same time, the design of the dust removal protection is more strict, so that the air volume is not leaked and the dust removal effect is increased. (4) Increase the intelligent monitoring system to track the cutting status in real time and reduce the accident rate. (5) Increase the follow-up system and automatic patrol system to improve the cutting effect and cutting efficiency. (6) The automatic lubrication system is upgraded. On the basis of the lubrication of the guide rail, the gear and screw lubrication components are added, and the lubricating oil is provided at regular intervals to ensure the normal operation of the equipment and prolong life time of the equipment. (4) The overall design is ergonomic, and the appearance is simple, atmospheric and practical. |

|

Samples

Customer comments

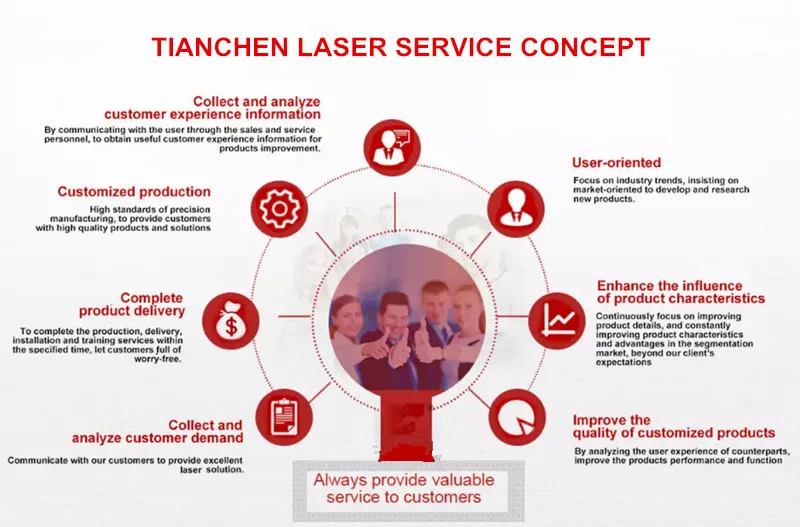

Our service

Factory