1.It is more convenient to use an industrial computer with an ultra-long screen, and it is more in line with the habit of using a

mobile phone. 2.Pressure-resistant explosion-proof water pipes and air pipes ensure the safety and stability of the machine under

special circumstances running. 3.Highly flexible and anti-break cables that can shield external interference signals

4.High-strength machine body leveling feet, more adaptable to different venues of customers, ensuring high-quality running cutting

5.Professional serrated blades

007TECH

JX Construction works fiber laser cutter full encirclemen high precision wide enlargement cutter fiber laser cnc for metal

JX Construction works fiber laser cutter full encirclemen high precision wide enlargement cutter fiber laser cnc for metal

Precio habitual

¥730.00 CNY

Precio habitual

¥730.00 CNY

Precio de oferta

¥730.00 CNY

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Products Description

Title goes here.

Product Paramenters

Model No. |

JX-6/9/12 large diameters steel tube cnc fiber cutter for tube cutting |

Cutting materials |

Steel square tube,round tube,oval tube,ractangle tube,angle steel, channel steel, H beam |

Cutting length |

6-12M |

Max.cutting diameter options |

220mm/320mm/420mm/500mm/600mm/800mm |

Cutting machine axis |

5 axis |

Transmission system |

Gear racks+rails |

Driving motors |

Servo |

X.Y maximum moving speed |

60m/min |

X, Y axis positioning accuracy |

±0.05/1000mm |

X, Y, Z axis repeat positioning accuracy |

±0.03/1000mm |

Fiber laser source |

Max/Raycus 1000W-12000W |

Cooling way |

Water cooling |

Cutting thickness |

Depends on different fiber source and materials |

Working voltage |

220V/380V |

Details Images

Advantages of JX-6/9/12 large diameters steel pipes CNC Fiber Laser Cutter

Designed for large sizes steel pipes. Cutting length 6-12M while diameter can reach 800mm at most.* It not only can cut round andsquare tubes, but also H beam, angle steel, channel steel,etc.

1.The overall double-bean design ensures stable and more precise operation.

2.Heavy-duty body design

3.The luxury model is fully surrounded by sheet metal, which can enhance the face of the factory when placed in the workshop.

Heavy-duty cast-steel structure, quenching treatment, no deformation, high precision. Rear chuck automatic feeding. Pneumatic

chuck and manual chuck options.

Samples

This machine is used for cutting metal round and square tubes, channel steel, angle steel etc. It adopts a 19-inch

high-resolution LCD color display, which can display cutting graphics and cutting running tracks. Cutting programs can be edited manually. It adopts five-axis perfect cutting, which can cut round pipe, square pipe, channel steel and angle steel . In addition, it supports functions such as pause, forward, backward, and speed regulation during processing. It can store 200G files and can be used at will. It is driven by high-efficiency servo motor, with fast speed, high efficiency, high precision and stable operation.

High-flexible shielded wire is used to truly resist high-frequency interference. It is suitable for various fiber optic models.

The movable beam can save tailings. The front chuck is equipped with two sets of intelligent follow-up splicing devices to

facilitate the For long material processing requirements, there is a set of intelligent follow-up material support systems in

between, so as to avoid Buyer’s long material sagging and affecting the cutting accuracy.

high-resolution LCD color display, which can display cutting graphics and cutting running tracks. Cutting programs can be edited manually. It adopts five-axis perfect cutting, which can cut round pipe, square pipe, channel steel and angle steel . In addition, it supports functions such as pause, forward, backward, and speed regulation during processing. It can store 200G files and can be used at will. It is driven by high-efficiency servo motor, with fast speed, high efficiency, high precision and stable operation.

High-flexible shielded wire is used to truly resist high-frequency interference. It is suitable for various fiber optic models.

The movable beam can save tailings. The front chuck is equipped with two sets of intelligent follow-up splicing devices to

facilitate the For long material processing requirements, there is a set of intelligent follow-up material support systems in

between, so as to avoid Buyer’s long material sagging and affecting the cutting accuracy.

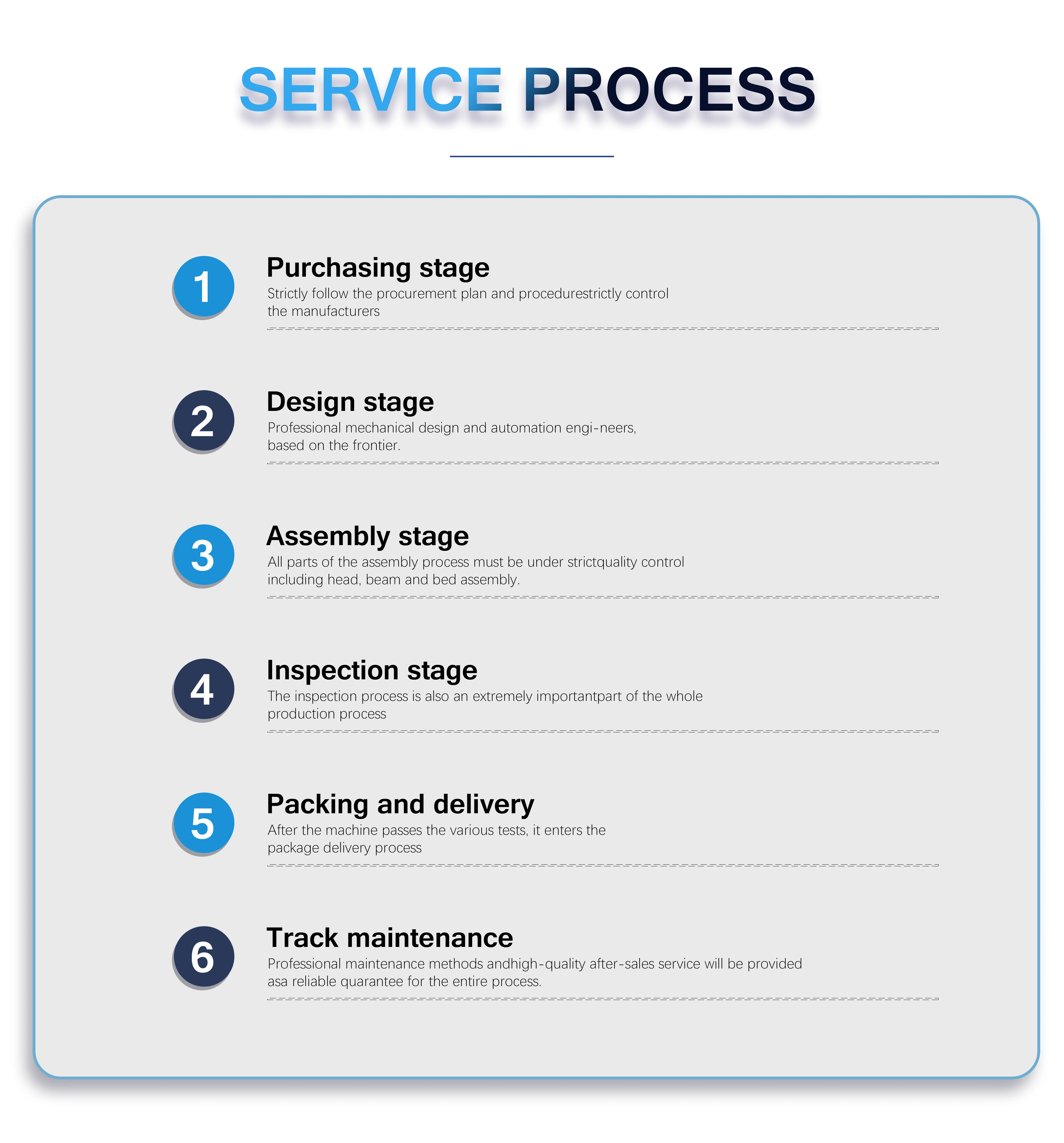

After service

Company Profile

Our Advantages

Certifications

Client Feedback

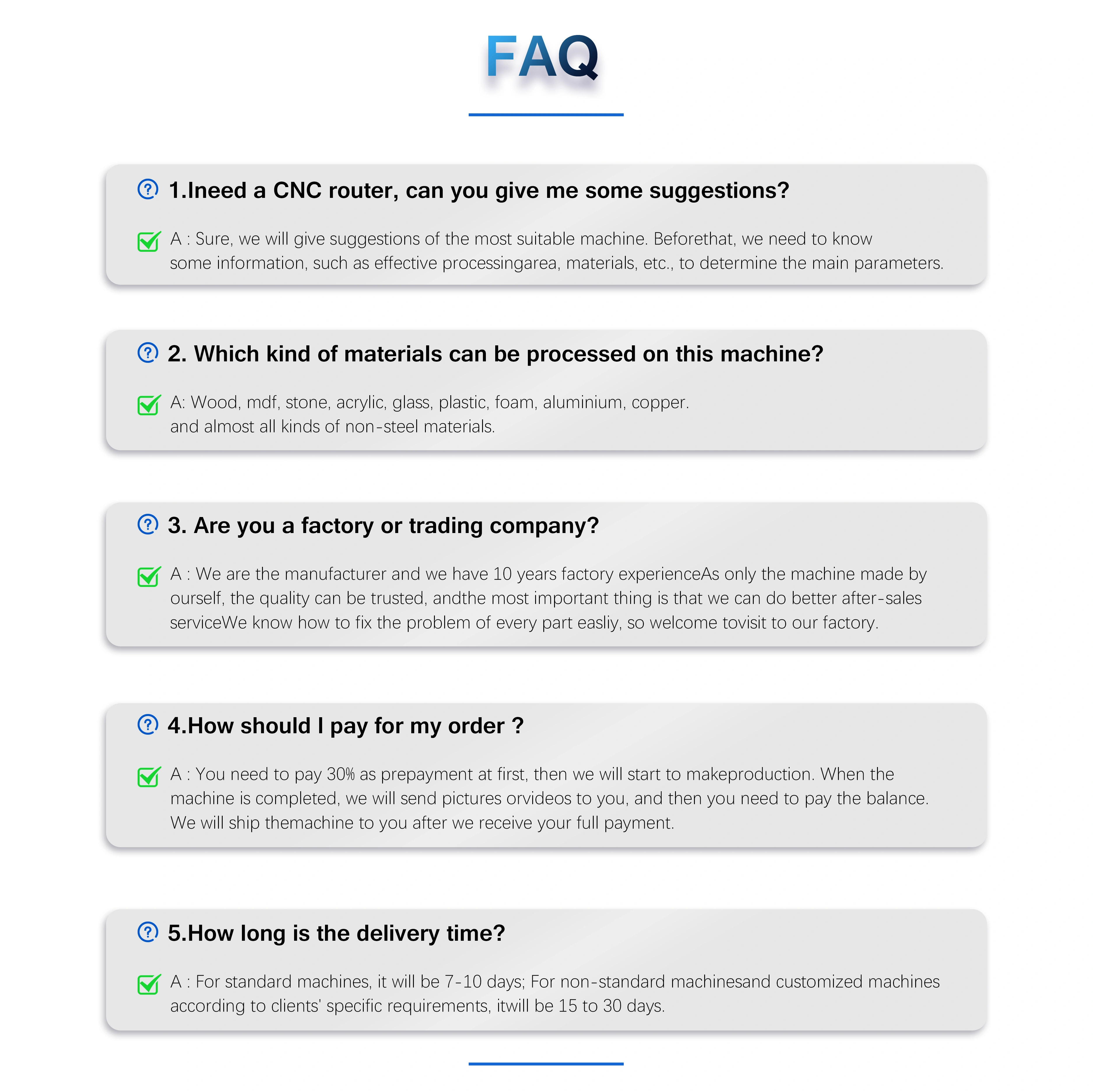

FAQ