Accurate Laser welding head is designed by the body engineering design method, fully considering the comfort of the customer for long-term use, and has the protective measures of the butt welding material to emit light, with multiple safety alarms, after removing, the workpiece lock light automatic, high security. Accurate laser welding head can be equipped with nozzles of different angles to meet the requirement of customers welding different products.

007TECH

laser welders 1500w handheld lazer welding machine 1000w 1500w 2000w 3000w For Welding Carbon Steel SS

laser welders 1500w handheld lazer welding machine 1000w 1500w 2000w 3000w For Welding Carbon Steel SS

Precio habitual

¥730.00 CNY

Precio habitual

¥730.00 CNY

Precio de oferta

¥730.00 CNY

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Welding Machine

Laser Welding Machine 1000w Handheld Fiber Laser Welding Machine For Welding Carbon Steel

Product Description

Details Images

Introduction

Portable handheld welding head

Portable handheld welding head is the biggest character of the machine.

Instead of the fixed welding head, it offers so much welding convenience for welding big ,or heavy ,or complex structure articles.

Laser source

Continuous laser source assure the high quality output beam and the stable output power.

We offer imported and China laser source for your choice ,includes IPG ,Raycus ,JPT,etc.

Welding software

Welding software is easily operated as the mode of human-computer interface. Strong software function can be realized by simple touch screen .It has editable and memory functions.

Samples

Model features and advantages

1.The welding speed is 2-10 times faster than the traditional welding. One

machine can save at least 2 welders a year.

2. The operation is simple, and it is possible to get on the job without a job

certificate, and the beautiful product can be welded without a teacher.

3. Smooth and beautiful welds, reducing subsequent grinding processes, saving

time and costs.

4. The LP welding head compensates for the small disadvantage of the laser welding

spot, expands the tolerance range of the machined parts and the weld width to obtain

better weld formation.

5. The welding workpiece has no deformation, no welding scars, and the welding is

firm.

6. Laser welding consumes less material and has a long life.

7. Safer and eco-friendly.

Our service

Significant advantages

Different welding of non-standard metal parts, manual welding is more flexible.Perfect welding quality, small deformation, high

penetration depth, no weld penetration.

A variety of welding processes, spot welding, seam welding, welding, etc.

High welding efficiency, replacing traditional TIG welding equipment.

The largest welding benefit cost, no consumables, energy saving and environmental protection.

penetration depth, no weld penetration.

A variety of welding processes, spot welding, seam welding, welding, etc.

High welding efficiency, replacing traditional TIG welding equipment.

The largest welding benefit cost, no consumables, energy saving and environmental protection.

Company Profile

Workshop

Visiting & Exhibition

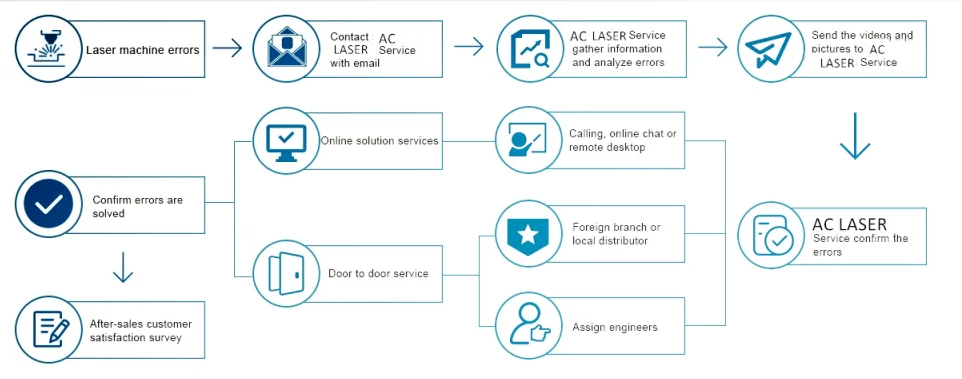

After-sales Service

FAQ

Q1: I knew nothing about this machine, what kind of machine should I choose?

A1: Tell us your material, detail requirements by

words, pictures or video. We will recommend you the suitable model with the reasonable price.

words, pictures or video. We will recommend you the suitable model with the reasonable price.

Q2: Who can help me transport the machine?

A2: We can arrange the shipment for you. Just tell us which port is near to you, so that we can check the exactly freight fee and shipping time for you.

Q3: When I got this machine, but I don't know how to use it. What should I do?

A3: We have the guide book, operational manual and training video with the machine. We have online support too.

Q4: If some problems happen to this machine during warranty period, what should I do?

A4: We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service.

Q5: How does your factory do regarding quality control?

A5: Quality is priority. We always pay great importance to quality control all over the way. All raw material we used are environmental-friendly. Skillful workers care every details in handling the producing and packing processes. Quality Control Department is specially responsible for quality checking in each process.