China MAX laser, with high quality and low price, is the choice of most customers. You can also choose other brands of lasers,

such as Rayces, BWT etc.

1

/

of

0

007TECH

2024 best selling lazer welding cleaning machine 1000w 2000w 3000w handheld fiber laser welding machine for welding metal

2024 best selling lazer welding cleaning machine 1000w 2000w 3000w handheld fiber laser welding machine for welding metal

Regular price

¥22,087.00 CNY

Regular price

¥22,087.00 CNY

Sale price

¥22,087.00 CNY

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Product Overview

MAX laser source

Touch Screen

Change the welding parameters via the touch screen control panel. The user could save the normal using parameter inside the system,and fast setting it before work.

Control Switch

Laser switch: give the start for the laser control system.

Power switch: give the electrical power on for the whole machine.

Emergency Stop: use this to protect the operator from the danger during the working.

Laser Head

Handheld light Laser Welding head, only with 700g weight, which makes operator work more longer time per day. There have double

protective lens, and the Temperature Sensor inside the laser head, which give the biggest protection.

protective lens, and the Temperature Sensor inside the laser head, which give the biggest protection.

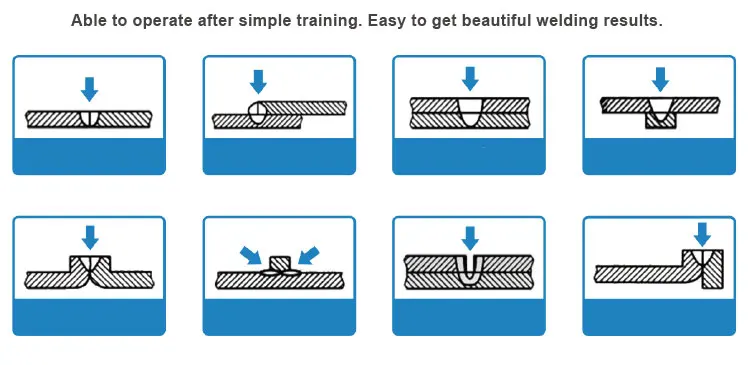

Nozzle and Lens

Customized special nozzle for meet different work. Help use get the better welding effect. Whole machine very easy to learn, one person only need 10 minutes to become the skilled worker.

Free gift for nozzles and lens

Safety Clip

There have the red safety clip on the side of the laser head. The operator must fix the clip on the metal materials, then the machine could normal working. This is the protection for the operator, which give the more safe working environment.

Auto Wire Feeder

Our wire feeding system support max 3.0 mm diameter metal wire, and with the double motor inside the machine case, which give the

more stable support for the machine working.

more stable support for the machine working.

1. Adopt integrated structure, that's its control system, laser system and cooling system are all built-in and integrated.

2. Handheld holding welding head is easily operated, picking and moving.

3. Using the fiber laser source. The laser beam quality is quite good, and its output power is stable which can assure the high welding performance.

4. The machine is with the safety control box, which can control the laser beam only comes out when welding starts.

5. Using special welding software .It has function of continuous laser beam, and the adjustable output waveform , which can assure the precious and high-speed welding.

6. It costs very low working consumption. Using laser machine one hour only consume 1-1.5 degree electricity, and weld all kinds of thin metal plates.

7. It can weld a wide range of metal, includes the stainless steel, carbon steel, cooper ,aluminum alloy , Zinc plated board.

8. Very nice welding performance .No deformation, small thermal effect.

9. 2-step trigger and welding part contact sensor enhance operator safety.

10. Safety interlock verifies integrity of laser delivery to the welding gun.

11.Machine can be equpped with automatic filler wire system, laser power 1000W can be filed with a diameter of 0.8-1mm welding wire, and for the laser power 1500W and 2000W can be filled with a diameter of 1.2mm welding wire, even if there are gaps in the welding position can also be efficient welding.

PRODUCT SPECIFICATIONS

Laser power |

1000W/1500W/2000W |

Laser wavelength |

1070 NM |

Fiber length |

10M ~15M |

Working mode |

Continuous / modulation |

Welder speed |

0~120 mm/s |

Cooling water |

Built-in water cooler |

Temperature |

15~35 ℃ |

Welding thickness |

0.5-3mm |

Welding penetration depth |

0.1-3mm |

4 IN 1 LASER WELDING MACHINE WELDING SAMPLES

4 IN 1 LASER WELDING MACHINE CLEANING SAMPLES

4 IN 1 LASER WELDING MACHINE CUTTING SAMPLES

4 IN 1 LASER WELDING MACHINE WELD SEAM CLEANING SAMPLES

FEATURES AT A GLANCE

LASER WELDING MACHINE EFFECT

Welding Thickness

1. 1000w/1kw handheld laser welder can weld 0.5-3mm steel; 2. 1500w/1.5kw fiber laser welder is used to weld 0.5-4mm steel;

3. 2000w/2kw laser welder can weld 0.5-5mm steel,0.5-4mm aluminum.

The above data is based on the triangular light spot. Due to the difference of the plate and labor, please refer to the actual welding.

1. 1000w/1kw handheld laser welder can weld 0.5-3mm steel; 2. 1500w/1.5kw fiber laser welder is used to weld 0.5-4mm steel;

3. 2000w/2kw laser welder can weld 0.5-5mm steel,0.5-4mm aluminum.

The above data is based on the triangular light spot. Due to the difference of the plate and labor, please refer to the actual welding.

Application

Magick laser welding machine is widely used in cabinet kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home.

Packing&Shipping

1. Test the machine before shipment and send the test videos/pics to customers

2. Use plastic film and foam packaging machine

3. Packing machine with reinforced wood case

2. Use plastic film and foam packaging machine

3. Packing machine with reinforced wood case

Company Profile

Magick Laser

Shandong Magick Intelligent Technology Co., Ltd. is a professional manufacturer of Industrial Laser Equipment. Our machines are widely used in metal processing industry. All of our products have passed I S O, C E, RoHS agency testing. We are a reliable supplier of laser equipment, providing 2-3 years of complete quality assurance services to ensure customer experience. We have professional engineer support, high efficiency sales team and competitive price superiority, and attract customers from all over

the world, We export to more than 100 countries.

the world, We export to more than 100 countries.

10

MORE THAN 10 YEARS PROFESSIONAL MANUFACTURER

130

TRUST AND RECOGNITION FROM 130+ COUNTRIES AND REGIONS

200

PROFESSIONAL TECHNICAL TEAM OF OVER 200 PERSONS

5000

DEEP COOPERATION WITH 5,000 ENTERPRISES

50000

HIGH-LEVEL PROFESSIONAL FACTORY WITH OVER 50,000 ㎡

25

25 PATENTS AND CERTIFICATES

FAQ

Q1. How to get the most suitable machine and best price

please tell the material you want to working on?How to working on it ? Engraving ? Cutting ? Or other ?

What’s the MAX size of these material ?( length ? Width ? Thickness ?)

Then we will supply you 2-3 solution for advice.

Q2. What is the payment?

The payment is 30% or 50% T/T or Alibaba trade assurance in advance,the balance prior to the shipment.

Q3. What is the producing time after order?

The production time is about 10-20 days depend on the exact machine and the quantity.

Q4. If we don't know how to use the machine,can you teach us?

Yes,we will ,if you come to China,we will offer you free training until you can use machine freely.And if you are busy ,we will

have the special engineer to your country,but you need to bear some fee,like tickets and hotel and meal.

Q5. How about your after-sales service?

we offer you 24 hours service phone,skype or what’sapp, our engineer also can go to door install or training.

Q6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The

complete machine will be tested to make sure they can work very well before being out of factory.The testing video and pictures

will be sent to you before the delivery.

please tell the material you want to working on?How to working on it ? Engraving ? Cutting ? Or other ?

What’s the MAX size of these material ?( length ? Width ? Thickness ?)

Then we will supply you 2-3 solution for advice.

Q2. What is the payment?

The payment is 30% or 50% T/T or Alibaba trade assurance in advance,the balance prior to the shipment.

Q3. What is the producing time after order?

The production time is about 10-20 days depend on the exact machine and the quantity.

Q4. If we don't know how to use the machine,can you teach us?

Yes,we will ,if you come to China,we will offer you free training until you can use machine freely.And if you are busy ,we will

have the special engineer to your country,but you need to bear some fee,like tickets and hotel and meal.

Q5. How about your after-sales service?

we offer you 24 hours service phone,skype or what’sapp, our engineer also can go to door install or training.

Q6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The

complete machine will be tested to make sure they can work very well before being out of factory.The testing video and pictures

will be sent to you before the delivery.