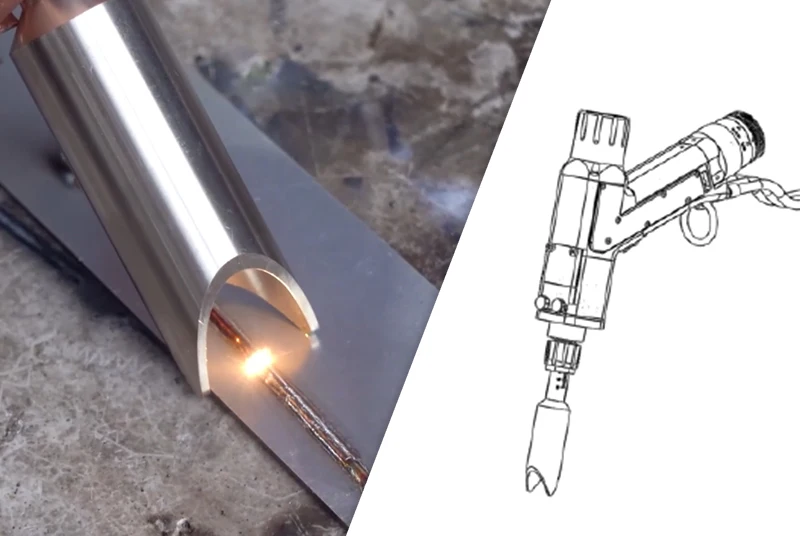

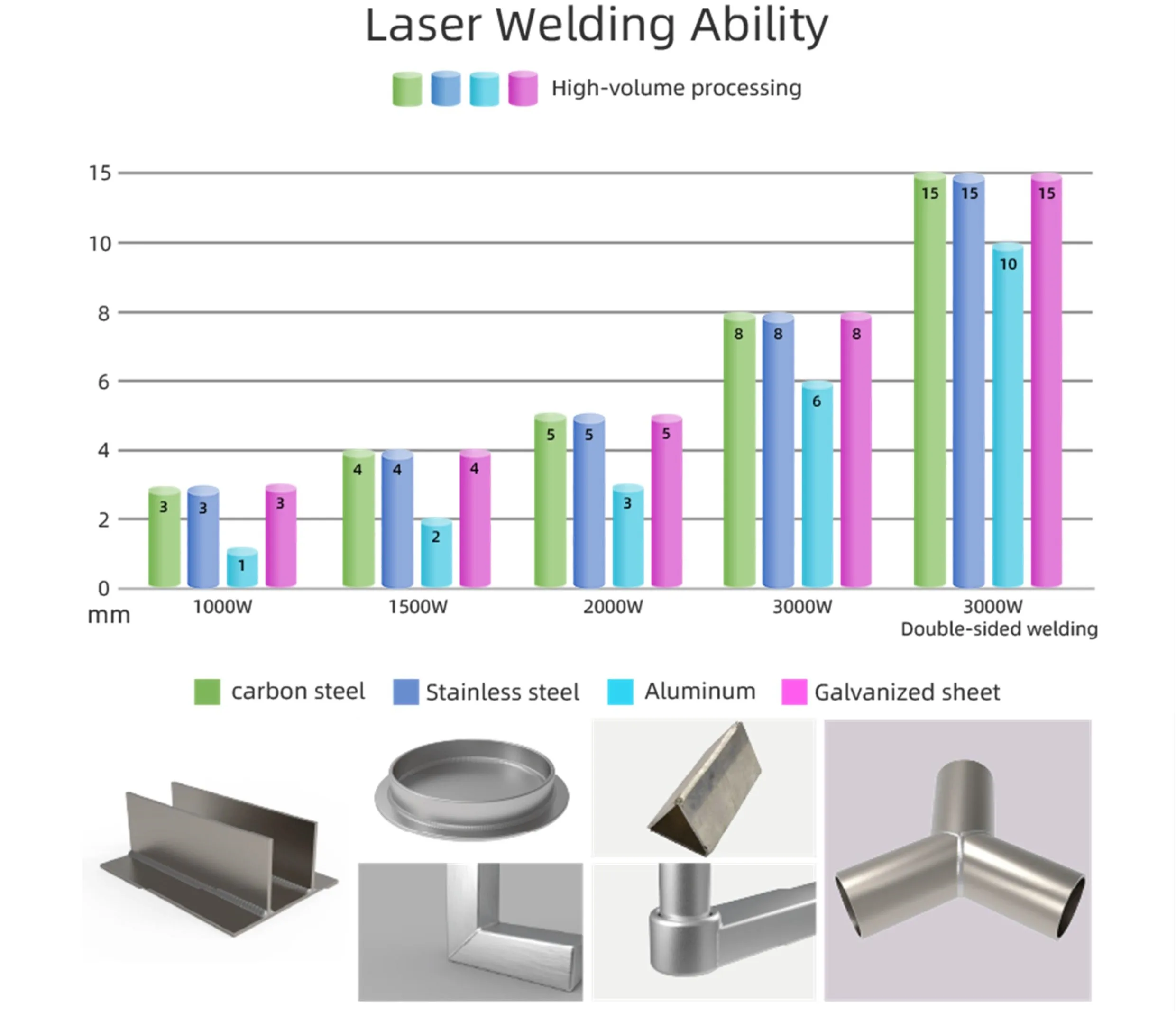

4 in 1 Fiber Laser Machine combined with 4 kinds of functions in 1 machine, for laser Cleaning, Cutting, Welding and Weld Seam Cleaning. With the best value for the NO.1 in the Laser Equipment. In the same time, it's very easy to operate, and change functions. When you need to clean metals, all you need to do is change certain parts on the Laser Head, we also have clear videos to help you finish this job.

Appearance