007TECH

DLX Factory Supply 1kw 1.5kw 2kw portable handhold fiber laser welders / handheld fiber laser welding machine

DLX Factory Supply 1kw 1.5kw 2kw portable handhold fiber laser welders / handheld fiber laser welding machine

Couldn't load pickup availability

DLX Factory Supply 1kw 1.5kw 2kw portable handhold fiber laser welders / handheld fiber laser welding machine

Laser Welding Machine Features:

1: Red light assisted positioning, welding does not offset

2: The theoretical life is up to 100,000 hours maintenance-free

3: CNC screen operation interface, concise and intuitive and easy to understand

4: Choose a robot or a positioner according to your needs

5: 5-10 times of argon arc welding, no need for professional welders to operate

6: Simple training for ten minutes, smooth welding effect is good

7: The welding is beautiful without deformation, and the post-processing is simple and easy

8: Special circuit feedback signal, lift the gun away from the workpiece without light

Parameter of the Laser Welding Machine:

| Model NO | NF-SC-1000 | NF-SC-1500 | NF-SC-2000 | NF-SC-3000 |

| Welding method | Handheld Welding (with automation available) | |||

| Welding materials | Stainless steel, iron, carbon steel, aluminum, aluminum alloy, copper, galvanized sheet, etc. | |||

| Weld penetration | 0.8-10mm | |||

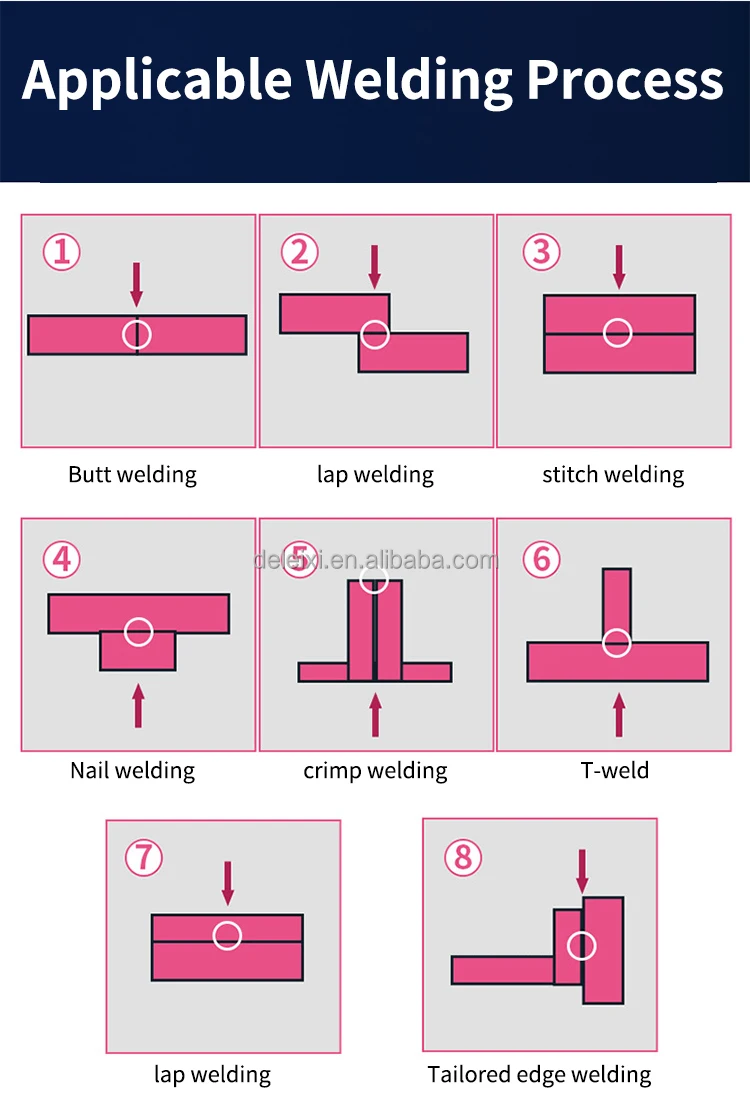

| Weld form | Butt welding, lap welding, stitch welding, riveting welding, crimp welding, T-welding, lap welding, tailor welding, etc. | |||

| Weld width | 0.5-5mm | |||

| Assisted positioning | red light | |||

| Welding gas | Argon/Nitrogen/Compressed Air (anhydrous) | |||

| Welding speed | 1-120MM/S | |||

| Fiber length | 10M | |||

| Welding plate thickness | 0.3-10MM | |||

| Cooling method | water cooling | |||

| Voltage | 220V/380V 50/60Hz | |||

| Dimension | 1200*650*1100MM | |||

| Weight | 160-220KG | |||

Laser welding is a kind of processing method of welding materials with high energy density laser beam as heat source. It has the advantages of simple operation, beautiful weld seam, fast welding speed and no consumables.

1.Fast cooling rate, fine weld seam, high precision.

1. Packaging: 1)Wrapped by proctective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Shipping: By logistics; by automobile; by train; by shipping; by air etc.

Changge Deleixi Machinery Equipment co. LTD is a manufacturer of processing machine our products include steel bar cutting machine,steel bar bending machine,straightening cutting machine,stirrup bending machine,plate compactor,tamping rammer ,trowel machine and so on, with well-equipped testing facilities and strong technical force.With a wide range, good quality, reasonable prices and stylish designs, our products are very popular in Mid-east,Africa,European ,American .ect, they are widely used in building ,road,railway and other area.Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs.We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

1.We have more than10 years manufacture and export experience.

2.Exporting to all over the world,win high reputation among customers.

3.CE, ISO 9001 and Strict Production Guideline to guarantee the high quality of our products.

4.Near the Qingdao port convenient for exporting.

5.Customer service staff 24 hours online,offer free technical support.

6.Factory and Competitive Price we offer.

7.Strong Research & Development technical team.

8.Various machinery to meet all your needs at our factory.

9.Engineers are available to guide the installation and take care of other problems.

10.We offer OEM&ODM service to meet all your requirements.

1) How can I place order?

A: You can contact us online, email, whatsapp or wechat, send me your order detailes, then I can help you place order..

2) How can I pay you?

A: After you confirm our PI, then you can pay the bank account by TT, or bank transfer, or pay online.

3) What's the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be

requested to do pr -epaid full payment or deposit before we go into production. After we get the deposit, we start to process the

order. We usually need 7-15days if we don't have the items in stock. Before production has been finished, we will contact you for

shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

4)How do you check all the goods in the production line?

A: We have spot inspection and finished product inspection. We check the goods when they go into next step production procedure.