High accurate and easy opreate

Portable handheld welding head is the biggest character of the machine. Instead of the fixed welding head,it offers so much

welding convenience for welding.

1

/

of

1

007TECH

Factory Price 1500W/2000W Handheld CQWY Fiber Laser Welding Machine 3-in-1 Steel Stainless Steel Iron New Condition Retail

Factory Price 1500W/2000W Handheld CQWY Fiber Laser Welding Machine 3-in-1 Steel Stainless Steel Iron New Condition Retail

Regular price

¥729.00 CNY

Regular price

¥729.00 CNY

Sale price

¥729.00 CNY

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Specification

Product Description

NO. |

Machine model |

MWG-1000H /MWG-1500H/ MWG-2000H |

||||||

1 |

Max laser power |

1000W 1500W 2000W |

||||||

2 |

Laser source |

Raycus/Max brand from China;IPG brand from Germany |

||||||

3 |

Beam quality |

1.3m² |

||||||

4 |

Laser wavelength |

1080±5nm |

||||||

5 |

Welding head |

ADM brand with QBH |

||||||

5 |

Water chiller |

BY1000;Double temperature dual control |

||||||

6 |

Power required |

380V±10%/50Hz |

||||||

7 |

Power Consumption |

6KW |

||||||

8 |

Fiber optical length |

10m |

||||||

Laser welding is a new type of welding method and one of the important aspects of the application of laser material processing technology. Laser welding is mainly for the welding of thin-walled materials and precision parts. The welding process is of thermal conductivity type, that is, the surface of the workpiece is heated by laser radiation, and the surface heat Diffusing into the interior through heat conduction, and by controlling parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool. It can realize spot welding, butt welding, stitch welding, sealing welding, etc., with high aspect ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful weld, no need to handle or just need to be processed after welding Simple processing, high weld quality, no air holes, precise control, small focus spot, high positioning accuracy

Hand-Held welding head

Auto Filler

wire-thickness :

0.6 – 0.8mm-1.0mm-1.2mm-1.5mm

0.6 – 0.8mm-1.0mm-1.2mm-1.5mm

Laser source and Chiller

Adopting famous brands (Raycus, JPT, MAX, IPG and other brands), the photoelectric conversion rate is greatly improved, laser

power is enhanced, has better welding effect, can according to the needs of customers with different configurations to meet

customer needs.

One of the biggest convenience of the machine is the inside water chiller. It saves a lot of the machine's dimension.It is

constant temperature industrial type.

power is enhanced, has better welding effect, can according to the needs of customers with different configurations to meet

customer needs.

One of the biggest convenience of the machine is the inside water chiller. It saves a lot of the machine's dimension.It is

constant temperature industrial type.

Our Advantages

Tig Welders |

Laser Welders |

|

Heat input |

Very high heat |

Very low calories |

Deformation |

Easy to deform |

No deformation |

Welding spot |

Large welding spot |

Fine welding spot, adjustable spot |

Exterior |

Unsightly, need polishing |

Smooth and beautiful, no need to sand |

Perforation |

Easy to pierce |

Not easy to perforate, can be controlled |

Protective gas |

Need argon |

Need argon |

Precision |

general |

Precision |

Processing time |

Long time |

Short time |

Safety |

Ultraviolet light, radiation |

Radiation-free |

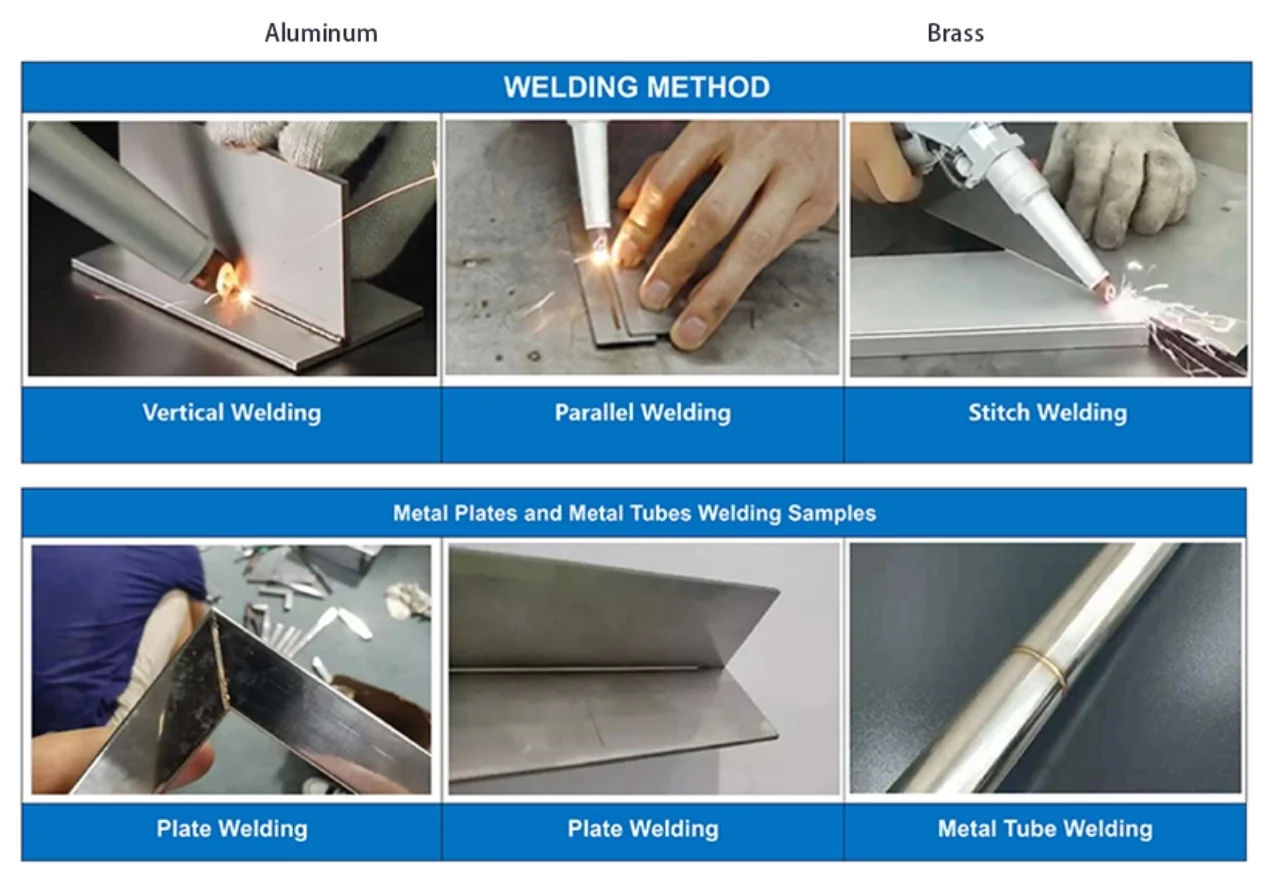

The handheld laser welding machine replaces the traditional fixed optical path with a new generation of handheld welding torch,which is flexible and convenient, and overcomes the limitation of the worktable space. The size of the workpiece

When it is not uniform, automatic welding is not possible. Mainly for large work pieces, fixed positions such as inner right angles, outer right angles, and flat welds.During welding, the heat-affected area is small, the deformation is small, the welding depth is large, and the welding is firm. It is a new welding process for long-distance welding of large work pieces.

Laser welding can weld difficult-to-access parts and perform non-contact long-distance welding with great flexibility.

When it is not uniform, automatic welding is not possible. Mainly for large work pieces, fixed positions such as inner right angles, outer right angles, and flat welds.During welding, the heat-affected area is small, the deformation is small, the welding depth is large, and the welding is firm. It is a new welding process for long-distance welding of large work pieces.

Laser welding can weld difficult-to-access parts and perform non-contact long-distance welding with great flexibility.

Features

1. The hand-held welding gun replaces the previous fixed optical path, which is more flexible and convenient, realizes

long-distance laser welding, and overcomes the limitation of the workbench stroke space;

long-distance laser welding, and overcomes the limitation of the workbench stroke space;

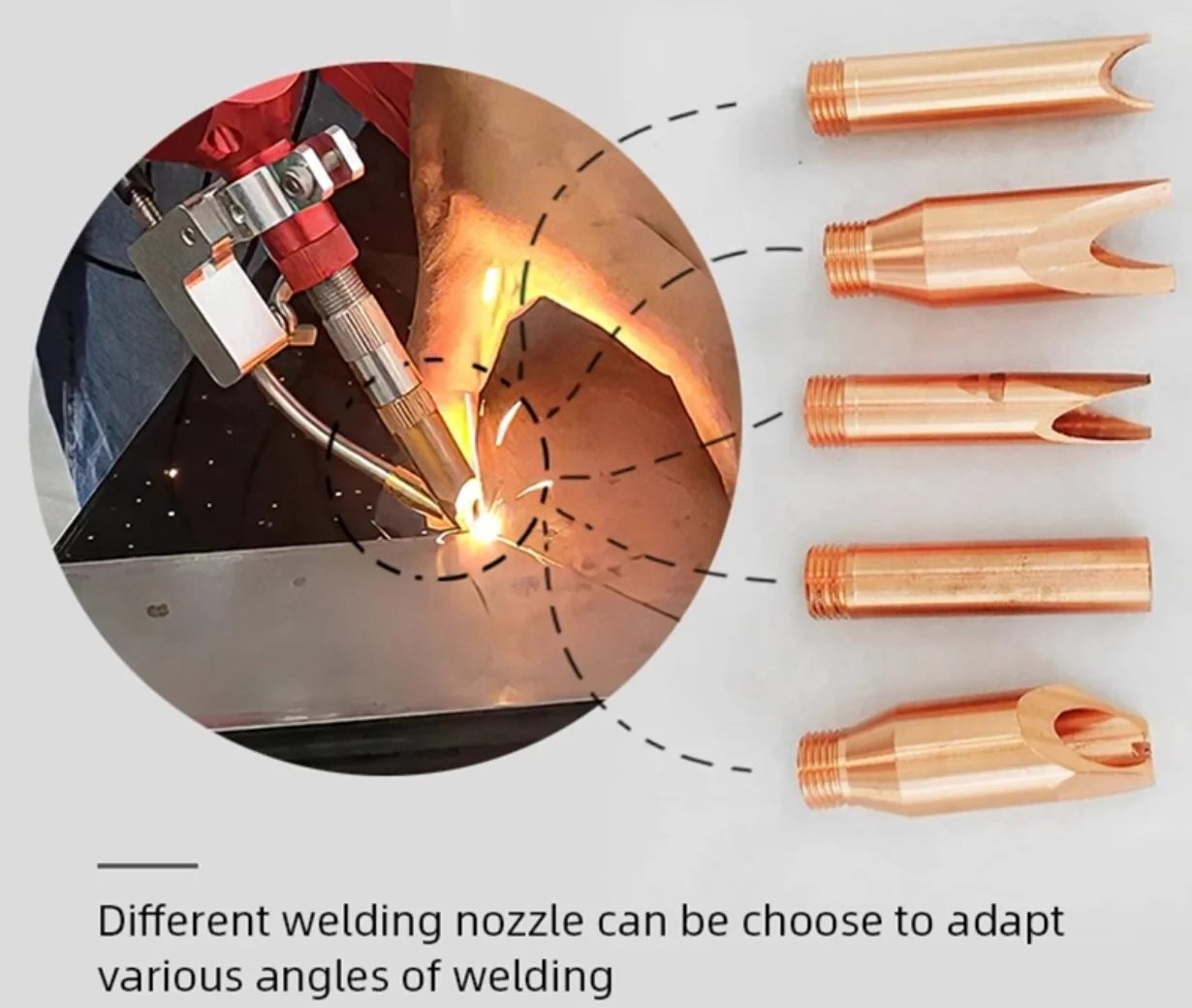

2. The hand-held welding head is light and flexible, and the operation is convenient and simple, which can meet the welding of various angles and positions;

3. Infrared positioning is used for welding head position verification and position verification during welding. The welding position is more accurate and the welding seam is more beautiful;

4. The laser welding depth is large and the welding is firm;

5. It is not easy to deform, easy to be polished, and solves the problems of weld penetration, weld bead, welding quality and so on when using argon arc welding;

6. It is also suitable for various complex welding seams and spot welding of various devices.

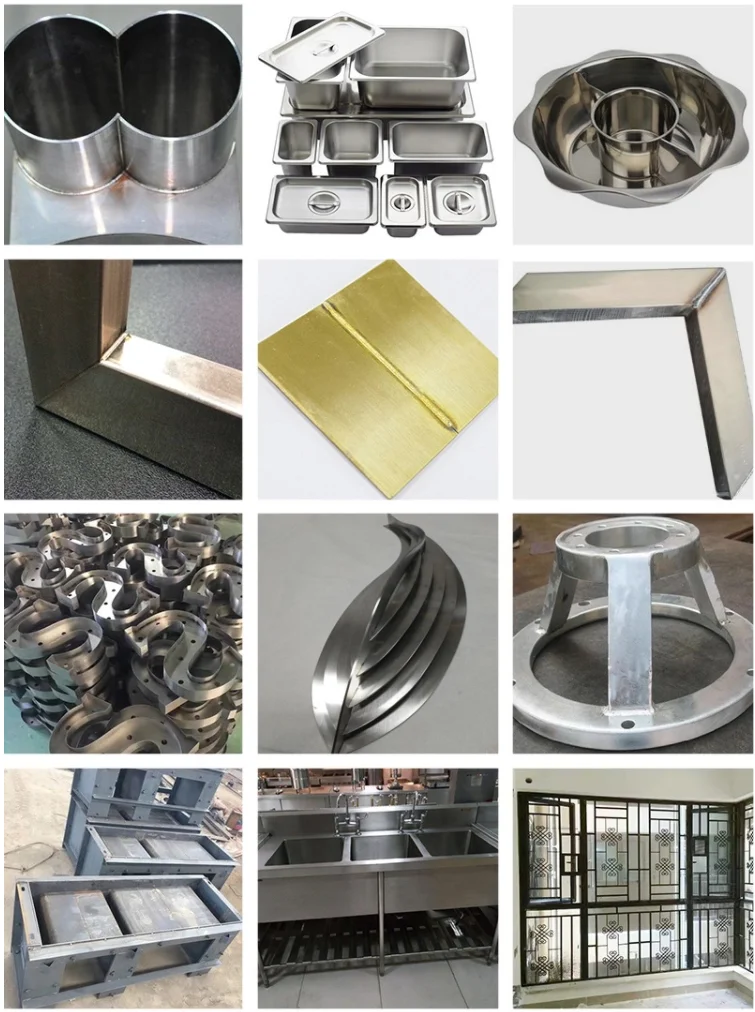

Application

1. Laser welding of sheet metal, chassis and water tank.

2. All kinds of hardware and lighting laser welding machine

3. Laser welding of door and window frames

4. Laser sealing welding of kitchen, bathroom and wash basin hardware

5. Laser welding of billboards and advertising characters Suitable for most metals such as stainless steel, titanium, water-plated plate, iron sheet, aluminum copper and other materials.

1kw welding ability |

||||||

No. |

Material |

Depth of fusion |

Penetration thickness |

|||

1 |

Stainless Steel |

≤4mm |

≤3mm |

|||

2 |

Mild steel/Iron |

≤4mm |

≤3mm |

|||

3 |

Galvanized sheet |

≤3mm |

≤2mm |

|||

4 |

Aluminum/brass |

≤2mm |

≤1mm |

|||

1.5kw welding ability |

||||||

No. |

Material |

Depth of fusion |

Penetration thickness |

|||

1 |

Stainless Steel |

≤5mm |

≤4mm |

|||

2 |

Mild steel/Iron |

≤5mm |

≤4mm |

|||

3 |

Galvanized sheet |

≤4mm |

≤3mm |

|||

4 |

Aluminum/brass |

≤3mm |

≤2mm |

|||

2kw welding ability |

||||||

No. |

Material |

Depth of fusion |

Penetration thickness |

|||

1 |

Stainless Steel |

≤6mm |

≤5mm |

|||

2 |

Mild steel/Iron |

≤6mm |

≤5mm |

|||

3 |

Galvanized sheet |

≤5mm |

≤4mm |

|||

4 |

Aluminum/brass |

≤4mm |

≤3mm |

|||

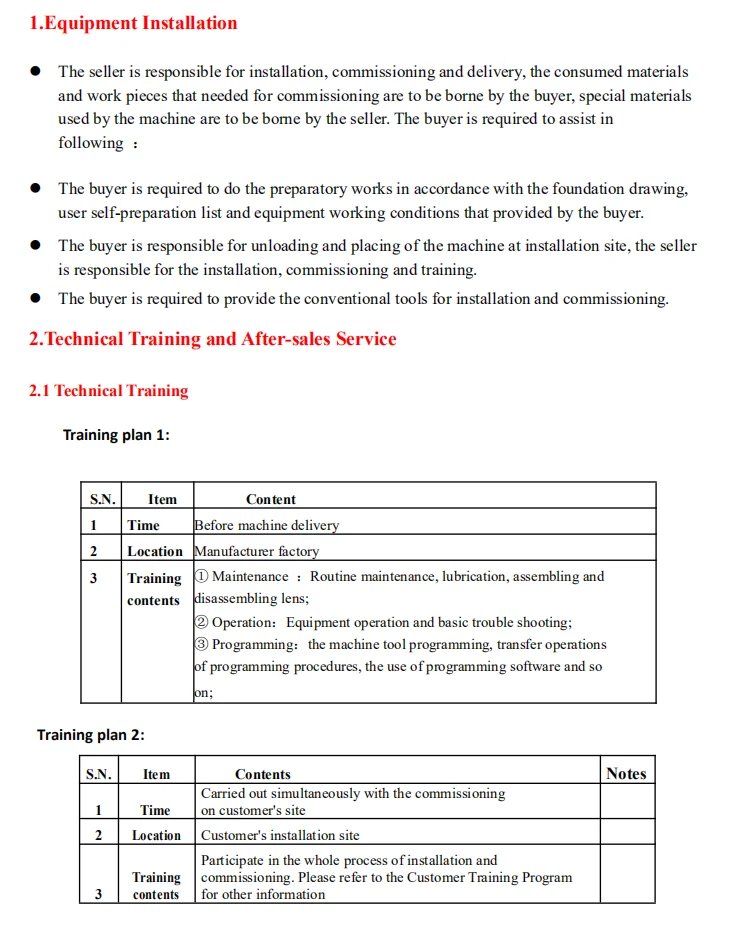

Equipment installation and after-sales

Packing & Delivery

Fiber laser welding Packaging and ShippingAll the machine parts have been packaging, and whole of the machine with waterproofing membrane. And then have been package use standard wood case (The fumigation-free ), on the case top and bottom have steel tube for support. Let it more strong to avoid damage during the transport and for long distance transportation.

1.Ply-wood case;1000*600*800cm,150kgs2.TWO Sets Ply-wood case;1000*600*800cm+ 1000*800*600mm,150kgs+80kgs

1.Ply-wood case;1000*600*800cm,150kgs2.TWO Sets Ply-wood case;1000*600*800cm+ 1000*800*600mm,150kgs+80kgs

Company Profile

Suzhou Alston D.M Laser Technology Co., Ltd is an ambitious fiber laser metal cutting machine manufacturer and exporter in China. We are also a service provider, including machine installation,

debugging, upgrading, maintenance and troubleshooting.

Our main products include laser cutting machine, laser marking machine, laser

welding machine and laser washing machine. They are widely used for the industries

include sheet metal, hardware, kitchenware, electronic, automotive parts, spectacles,

advertising, craft, lighting, decoration, jewelry, etc. Focusing on quality and service,

we are dedicated to providing customers with perfect sheet metal processing

solutions and high quality after-sales service.

FAQ

1. What is your Fiber Laser Cutting Machine Advantages?

Top-rated laser source: stable beam quality, long service life;

User-friendly control system: Easy to use, even a green hand can get started quickly;

Exceptional service: quick response, lifelong after-sales service, we are still serving customers’ who have built relationship

with us for more than 10 years

2. Do You Have Agents or Distributors in Our Country?

We have ender-users all over the world.At present, we have agency in India, Vietnam and Russia.If you are interested in agency cooperation, please contact us for detailed agency policy.

3. Are you a factory or a trading company?

We are factory, with headquarter in Suzhou,JIangsu province , and branch in Wuhan,Hubei province.

4. When I got this machine, but I don’t know how to use it. What should I do?

We will provide user manual and video of the machine. In addition, our engineer can also provide training online. If necessary, we

can also provide door-to-door service

5. If some problems happen to this machine during the warranty period, what should I do?

We will provide 2-3 Year Warranty, and will supply free parts during the machine warranty period if the machine has some problems.

We also supply free life long after-sales service. Thus, any problems, just feel free to let us know, we will provide you

solutions.

6. How to make the payment and how about the delivery time?

We accept to make the payment by T/T, Credit Card ,Online Bank Payment,etc.Lead time 10-15 working days for the standard

machine;Lead time 20-27 working days for a non-standard machine.

7. Q: How can I choose the most suitable machine?

A: In order to recommend you the most suitable machine model, please let us know the following detailes:

1.What is your material?

2.The size of material?

3.The thickness of material?

8. Q: If we need Yosoontechnician to train us after order,how to charge?

A:1) If you come to our factory to get training,it is free for learning, 1-3 working days.(Every one learning ability is

different,also according to details)

2) If you need our technician go to your local factory to teach you ,you need to bear the technician’s business travelling

ticket / room and board/ and additional 100 USD per day.

9. About accuracy, we have observed that after some time "Machine accuracy can increase gradually" and after long time, the difference reach to its maximum level. How about your machine?

The frame of the machine is annealed, it can support shock resistance(the machine will deform if without annealing ). So the accuracy of the machine can keep its original accuracy for 4-5years. The weight of the machine can reach 4.5t-5.0t. It also can let the machine have higher accuracy and higher stability.

10. What’s package, will it protect the products?How is the shipping method?

A: As per your actual address, we can effect shipment by sea, by air, by truck or railway. Also we can send the machine to your worksite as per your requirement . Nude Packing for big parts after plastic film covering. The small parts packed into wooden cases which is suitable for seaworthy transportation.

Top-rated laser source: stable beam quality, long service life;

User-friendly control system: Easy to use, even a green hand can get started quickly;

Exceptional service: quick response, lifelong after-sales service, we are still serving customers’ who have built relationship

with us for more than 10 years

2. Do You Have Agents or Distributors in Our Country?

We have ender-users all over the world.At present, we have agency in India, Vietnam and Russia.If you are interested in agency cooperation, please contact us for detailed agency policy.

3. Are you a factory or a trading company?

We are factory, with headquarter in Suzhou,JIangsu province , and branch in Wuhan,Hubei province.

4. When I got this machine, but I don’t know how to use it. What should I do?

We will provide user manual and video of the machine. In addition, our engineer can also provide training online. If necessary, we

can also provide door-to-door service

5. If some problems happen to this machine during the warranty period, what should I do?

We will provide 2-3 Year Warranty, and will supply free parts during the machine warranty period if the machine has some problems.

We also supply free life long after-sales service. Thus, any problems, just feel free to let us know, we will provide you

solutions.

6. How to make the payment and how about the delivery time?

We accept to make the payment by T/T, Credit Card ,Online Bank Payment,etc.Lead time 10-15 working days for the standard

machine;Lead time 20-27 working days for a non-standard machine.

7. Q: How can I choose the most suitable machine?

A: In order to recommend you the most suitable machine model, please let us know the following detailes:

1.What is your material?

2.The size of material?

3.The thickness of material?

8. Q: If we need Yosoontechnician to train us after order,how to charge?

A:1) If you come to our factory to get training,it is free for learning, 1-3 working days.(Every one learning ability is

different,also according to details)

2) If you need our technician go to your local factory to teach you ,you need to bear the technician’s business travelling

ticket / room and board/ and additional 100 USD per day.

9. About accuracy, we have observed that after some time "Machine accuracy can increase gradually" and after long time, the difference reach to its maximum level. How about your machine?

The frame of the machine is annealed, it can support shock resistance(the machine will deform if without annealing ). So the accuracy of the machine can keep its original accuracy for 4-5years. The weight of the machine can reach 4.5t-5.0t. It also can let the machine have higher accuracy and higher stability.

10. What’s package, will it protect the products?How is the shipping method?

A: As per your actual address, we can effect shipment by sea, by air, by truck or railway. Also we can send the machine to your worksite as per your requirement . Nude Packing for big parts after plastic film covering. The small parts packed into wooden cases which is suitable for seaworthy transportation.