1

/

of

0

007TECH

Handheld easy-operated cnc 1000w 1500w 2000w portable air-cooled laser welding machine / handheld laser rust removal for wood

Handheld easy-operated cnc 1000w 1500w 2000w portable air-cooled laser welding machine / handheld laser rust removal for wood

Regular price

¥22,110.00 CNY

Regular price

¥22,110.00 CNY

Sale price

¥22,110.00 CNY

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Handheld easy-operated cnc 1000w 1500w 2000w portable air-cooled laser welding machine / handheld laser rust removal for wood

Welcome to our factory,Here is a 360 degree panoramic display of our factory

Bulk purchases to obtain greater support from suppliers, lower purchase costs for the same product, and better after-sales policies

Features:

Handheld Fiber Laser Cleaning&Welding&Cutting Machine Description

The laser cleaning and welding machine can not only clean the metal surface contaminants, but also weld and combine various metal materials.

It is a mlti-functinal laser equipment. Equipped with Ruida system, it has two modes of cleaning and welding, which can be

flexibly switched.

1. Fast and concentrated pulses with enormous power impact and gasification of residues on the surface;

2. Laser pulses are verysuitable for the removal of organic matter, such as residues in the tire mold fouling;

3. The impact of a short period of timewill not cause metal surface heating, no damage to the substrate.

4. Clean or remove the surface paint layer quickly and cleanly;

5. Accurate cleaning and paint removal effect;

6. No damage to the base material.Cleaning Fiber laser cleaning head has a good cleaning effect on iron, carbon steel plate,stainless steel plate, mold steel gear, aluminum plate, paint layer and other materials. The laser cleaning mode can clean the oxide layer, remove the paint on the surface, clean the surface oil, stains and dit, clean the rubber mold residue.

Meet the requirements for equipment cleaning in the shipbuilding industry, auto parts, rubber molds, machine tools, environmental protection industries and other fields.

Handheld Fiber Laser Cleaning&Welding&Cutting Machine Description

The laser cleaning and welding machine can not only clean the metal surface contaminants, but also weld and combine various metal materials.

It is a mlti-functinal laser equipment. Equipped with Ruida system, it has two modes of cleaning and welding, which can be

flexibly switched.

1. Fast and concentrated pulses with enormous power impact and gasification of residues on the surface;

2. Laser pulses are verysuitable for the removal of organic matter, such as residues in the tire mold fouling;

3. The impact of a short period of timewill not cause metal surface heating, no damage to the substrate.

4. Clean or remove the surface paint layer quickly and cleanly;

5. Accurate cleaning and paint removal effect;

6. No damage to the base material.Cleaning Fiber laser cleaning head has a good cleaning effect on iron, carbon steel plate,stainless steel plate, mold steel gear, aluminum plate, paint layer and other materials. The laser cleaning mode can clean the oxide layer, remove the paint on the surface, clean the surface oil, stains and dit, clean the rubber mold residue.

Meet the requirements for equipment cleaning in the shipbuilding industry, auto parts, rubber molds, machine tools, environmental protection industries and other fields.

Product Description

Control System

Humanized design operation panel with touch control by hand, full functions including working mode of welding/cleaning/cutting, special laser source data monitoring page, technical information, support 8

languages to meet more customers' requirements.

Laser Welding Wire Feeder

Laser Welding Wire Feeder

Welding Head

Laser Cleaning Head

*easy to use and high efficiency protect modules for calibration and focus lens *Drawer-type of lens mount,quick and easy use

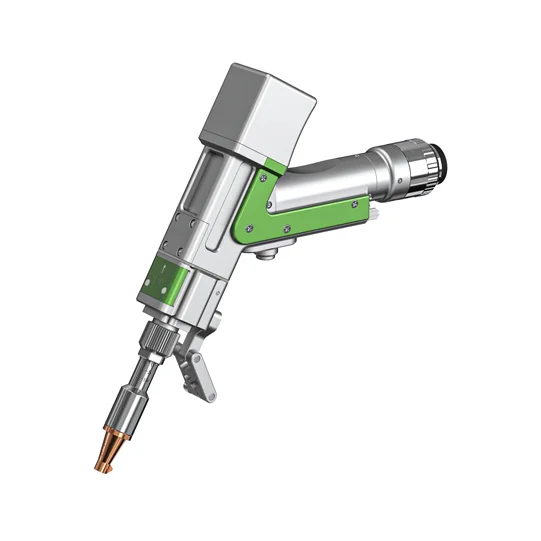

Laser Welding Head

*Easy to use and high efficiency. *Protect modules for calibration and focus lens Drawer-type of lens mount, quick and easy use

Laser Cutting Head

*Easy to use and high efficiency *Protect modules for calibration and focus lensDrawer-type of lens mount, quick and easy use

Specification

Model |

LM-WT-1000w |

LM-WT-1500w

|

LM-WT-2000w |

||

Laser source type |

Fiber source |

Fiber source |

Fiber source |

||

Function |

3 IN 1 Laser Welding&CLeaning&Cutting |

||||

Laser Out Power |

1000W |

1500W |

2000W |

||

Laser wavelength |

1070nm |

1070nm |

1070nm |

||

Laser Source |

Raycus/Max/IPG/JPT |

Raycus/Max/IPG/JPT |

Raycus/Max/IPG/JPT |

||

Focal spot diameter |

0.1-3mm |

0.1-3mm |

0.1-3mm |

||

Laser frequency |

1-50Hz |

1-50Hz |

1-50Hz |

||

Repeatability |

±0.01mm |

±0.01mm |

±0.01mm |

||

Machine operating temperature |

0~40℃ |

0~40℃ |

0~40℃ |

||

Electricity demand |

220V |

220V |

220V |

||

Cooling method |

Air Cooling |

Air Cooling |

Air Cooling |

||

Continuous operating time |

24 hours |

24 hours |

24 hours |

||

Weight |

103KG |

103KG |

103KG |

||

Dimensions |

83*83*80CM |

83*83*80CM |

83*83*80CM |

||

Laser control system |

Depeng Touch screen |

Depeng Touch screen |

Depeng Touch screen |

||

Samples Show

Rust removal:

100W laser rust removal cleaning process is one of the most effective, cost-saving and environment friendly rust removal methods.This machine can be used to clean all kinds of parts, such as metal, cast iron products and so on.

Paint removal:

100W laser rust removal cleaning process is one of the most effective, cost-saving and environment friendly rust removal methods.This machine can be used to clean all kinds of parts, such as metal, cast iron products and so on.

Paint removal:

The high quality laser removes corrosion and rust with the help of a special reflection coating. This 100w laser cleaner is 100% safe to use and all materials will be completely unaffected by the laser.

Oil Contamination Removal

With the 100W laser cleaning machine, you also have a machine perfect for clearing oil, grease, or other products from metallic and non-metallic materials. Therefore, it is an important laser cleaning machine if you work in the manufacturing and repair industry, where an accumulation of moisture, dirt, and grease is common.

Product protection:

This 100w rust cleaning laser machine is specially designed to clean old rusted iron and steel parts. It can remove rust on metal using a high-intensity laser, so that the surface of the metal becomes bright and spotless.

With the 100W laser cleaning machine, you also have a machine perfect for clearing oil, grease, or other products from metallic and non-metallic materials. Therefore, it is an important laser cleaning machine if you work in the manufacturing and repair industry, where an accumulation of moisture, dirt, and grease is common.

Product protection:

This 100w rust cleaning laser machine is specially designed to clean old rusted iron and steel parts. It can remove rust on metal using a high-intensity laser, so that the surface of the metal becomes bright and spotless.

Features of Handheld Laser Welding Systems:

Portability: The compact and lightweight design of handheld laser welding machines makes them highly portable.

High precision: These machines are capable of soldering with high precision, making them suitable for welding small parts or intricate components.

Fiber optic cable: These machines use a fiber optic cable to deliver the laser beam to the workpiece. The fiber optic cable is flexible and allows for easy maneuvering, allowing for the laser beam to be directed precisely where it's needed.

Adjustable focus: The laser beam can be focused to a very small point, allowing for welding with high precision. The focus can also be adjusted to different depths, making it possible to weld materials of various thicknesses.

Easy to operate: Handheld laser welders are typically easy to operate, with a user-friendly interface that allows for quick and simple adjustments.

Multifunction: Laser welding cleaning cutting machine with 5-in-1 function, includes 5 wire-feeding copper nozzles, 1 copper nozzle for outer corner welding, 1 dual wire-feeding copper nozzle for weld bead cleaning and 1 copper nozzle for cutting. The hand held laser welding machine is equipped with 6 copper nozzles, aiming to provide greater flexibility to meet various welding angles, materials, and effects.

Portability: The compact and lightweight design of handheld laser welding machines makes them highly portable.

High precision: These machines are capable of soldering with high precision, making them suitable for welding small parts or intricate components.

Fiber optic cable: These machines use a fiber optic cable to deliver the laser beam to the workpiece. The fiber optic cable is flexible and allows for easy maneuvering, allowing for the laser beam to be directed precisely where it's needed.

Adjustable focus: The laser beam can be focused to a very small point, allowing for welding with high precision. The focus can also be adjusted to different depths, making it possible to weld materials of various thicknesses.

Easy to operate: Handheld laser welders are typically easy to operate, with a user-friendly interface that allows for quick and simple adjustments.

Multifunction: Laser welding cleaning cutting machine with 5-in-1 function, includes 5 wire-feeding copper nozzles, 1 copper nozzle for outer corner welding, 1 dual wire-feeding copper nozzle for weld bead cleaning and 1 copper nozzle for cutting. The hand held laser welding machine is equipped with 6 copper nozzles, aiming to provide greater flexibility to meet various welding angles, materials, and effects.

Company Profile

Jinan Laser Max Machinery Tech Co.,Ltd

2013 Jinan was established

2015 developed rapidly , product sales exceeded 800 sets

2016 Laser Cutting Division was established

2018 over 2000 sets of machines been sold, beeing one of the well-known manufacturers of laser equipment in the world

2020 laser cutting factory which size over 8000 square meters was established in Jinan. Sales keeping growth rapidly, sales reach 120 million RMB.

2021, independently developed and produced the first 12,000 watt high-power laser cutting machine

2022, more than 10sets 12000W high-power laser cutting machines and 5sets 20000w laser cutting machines were delivered Laser Max with a decade of cumulative laser equipment design and manufacturing expertise

Laser Max focus on laser cutting machine, laser welding machine, laser cleaning machine, laser marking machines, customized and other series of more than 50 kinds of industry specific laser solutions.Having long-term with United

States,Russia,Mexico,Britain,Germany,Brazil,Korea,Turkey,India,Indonesia,Saudi Arabia and more than 50 countries' company in R&D cooperation Bulk purchases to obtain greater support from suppliers, lower purchase costs for the same product, and better after-sales policies

Laser Max is willing to share our advantages and resources with partners, and warmly welcome to cooperate with us

2015 developed rapidly , product sales exceeded 800 sets

2016 Laser Cutting Division was established

2018 over 2000 sets of machines been sold, beeing one of the well-known manufacturers of laser equipment in the world

2020 laser cutting factory which size over 8000 square meters was established in Jinan. Sales keeping growth rapidly, sales reach 120 million RMB.

2021, independently developed and produced the first 12,000 watt high-power laser cutting machine

2022, more than 10sets 12000W high-power laser cutting machines and 5sets 20000w laser cutting machines were delivered Laser Max with a decade of cumulative laser equipment design and manufacturing expertise

Laser Max focus on laser cutting machine, laser welding machine, laser cleaning machine, laser marking machines, customized and other series of more than 50 kinds of industry specific laser solutions.Having long-term with United

States,Russia,Mexico,Britain,Germany,Brazil,Korea,Turkey,India,Indonesia,Saudi Arabia and more than 50 countries' company in R&D cooperation Bulk purchases to obtain greater support from suppliers, lower purchase costs for the same product, and better after-sales policies

Laser Max is willing to share our advantages and resources with partners, and warmly welcome to cooperate with us

After-sell Service

What kind of support you can get from LASER MAX?

一. 3 year warranty,Provide a full range of technical support for life.

二. From monday to sunday 9am to 22pm. Experienced technician to guarantee lifetime online support(by whatsapp /skyper /wechat /email). So there is no need to worry about technical support due to time difference.

三. Support local after-sales service. up to 2022, we have offered onsite to these countries and areas: Canada, Mexico, the United States, Ukraine, Russia, Italy, Poland, Spain, Brazil, Indonesia, India, Turkey, Thailand, Vietnam, Australia,etc..

三. Support local after-sales service. up to 2022, we have offered onsite to these countries and areas: Canada, Mexico, the United States, Ukraine, Russia, Italy, Poland, Spain, Brazil, Indonesia, India, Turkey, Thailand, Vietnam, Australia,etc..

PACKAGE&DELIVERY

1. Cleaning the fiber laser cutting machine.

2. Wrap all the laser cutting machine parts with bubble film and plastic film.

3. Fix the machine with iron frame.

4. Wooden box sealing the fumigated plywood portection is finished.

5. Forklift the packed machine to the container.

6. Choose the optimal routes and transportation mode according to the distance.

2. Wrap all the laser cutting machine parts with bubble film and plastic film.

3. Fix the machine with iron frame.

4. Wooden box sealing the fumigated plywood portection is finished.

5. Forklift the packed machine to the container.

6. Choose the optimal routes and transportation mode according to the distance.

(1)Packaging:

Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

(2)Shipping:We cooperate with the company whose experience in the ocean transportation will guarantee your machine safety. We also

provide train transport, especially to Russia, Ukraine and other inland countries.

Whole film packaging machine; anti-collision package edge; fumigation-free plywood wooden box and pallets with iron binding belt.

(2)Shipping:We cooperate with the company whose experience in the ocean transportation will guarantee your machine safety. We also

provide train transport, especially to Russia, Ukraine and other inland countries.

Other Hot Sales

Below are other hot selling products from our factory

The Area Of Fiber Laser Cutting Machine

The Area Of Laser Welding&Cleaning Machine

The Area Of Jewelry Welding Machine

The Area Of Laser Engraving Machine

FAQ

Q1: Can you give us a better price?

A: Sure, we are the manufacture, we can offer not only good price but also good products and service.

Q2: Can I make a OEM order?

A: Sure it can be accepted, contact us to talk more details.

Q3: How does your factory do regarding quality control?

A: Quality control department is very important team in our Company, every steps we have test records.

Only after quality inspector stamp on the order, we can send the machine out.

Q4: What's your MOQ order?

A: It is 1 pcs but more orders can enjoy more discount.

Q5: How to find the right product?

A: Please provide us with your requirements of the machine, our team will give you professional suggestions.

A: Sure, we are the manufacture, we can offer not only good price but also good products and service.

Q2: Can I make a OEM order?

A: Sure it can be accepted, contact us to talk more details.

Q3: How does your factory do regarding quality control?

A: Quality control department is very important team in our Company, every steps we have test records.

Only after quality inspector stamp on the order, we can send the machine out.

Q4: What's your MOQ order?

A: It is 1 pcs but more orders can enjoy more discount.

Q5: How to find the right product?

A: Please provide us with your requirements of the machine, our team will give you professional suggestions.