1

/

of

1

007TECH

Portable 700W 1500W Air cooled handheld laser welding machine for industrial applications

Portable 700W 1500W Air cooled handheld laser welding machine for industrial applications

Regular price

¥736.00 CNY

Regular price

¥736.00 CNY

Sale price

¥736.00 CNY

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Product information

Unbeatable Benefits

●FAST: Up to 4X faster than TIG

●VERSATILE: Wide range of materials – up to 1/4 in. (6.35 mm)

●EASY: Optimized presets reduce learning curve

●CONSISTENT: High-quality, repeatable results

●FLEXIBLE: Simple and challenging applications

●PRODUCTIVE: Pre- and post-weld cleaning capability

Product Details

Model |

A70i |

A150i |

A200i |

||||||

Laser source |

700W |

1500W |

2000W |

||||||

Shielding Gas |

Argon,Nitrogen,Air |

Argon,Nitrogen,Air |

Argon,Nitrogen,Air |

||||||

Complete Penetration |

2mm |

4mm |

6mm |

||||||

Input power |

<2.2kw |

<4.5kw |

<6kw |

||||||

Cooling model |

Air cooling |

Air cooling |

Air cooling |

||||||

Mains supply |

AC220V 1PH |

AC220V 1PH |

AC220V 1PH |

||||||

Weight |

22kg |

38kg |

45kg |

||||||

LightWELD - Turnkey Handheld Laser Welding & Cleaning Systems

● Adjustable laser welding power up to 1500 W

●Preset & user-defined modes optimize material-thickness combinations

●Wobble welding controls for 5 mm of additional weld width

● Rear panel provides intuitive connections for power, process gas and external accessory controls

● Cleaning power up to 2500 W peak for greater welding quality and finishing capability

●Preset & user-defined modes optimize material-thickness combinations

●Wobble welding controls for 5 mm of additional weld width

● Rear panel provides intuitive connections for power, process gas and external accessory controls

● Cleaning power up to 2500 W peak for greater welding quality and finishing capability

Less Heat & Distortion for More Productivity & Flexibility

TIG welding is a time-consuming, two-handed welding method that requires an experienced, highly-skilled operator. TIG welding may

generate extreme heat that deforms thin materials, produces poor visual finishes, is difficult when welding copper, and limited when welding metals of dissimilar thicknesses.

generate extreme heat that deforms thin materials, produces poor visual finishes, is difficult when welding copper, and limited when welding metals of dissimilar thicknesses.

MIG welding requires consumable wire, material pre-cleaning and beveled joints for thick metals for full penetration. Travel and work angles are limited and vertical positions are extremely challenging.

LightWELD enables dramatically faster welding, is easier to learn and operate, and provides higher-quality, consistent results across a wider range of materials and thicknesses than MIG or TIG with minimal

distortion, deformation, undercut or burn-through.

Factory Presets Ensure Optimized Welds & Cleaning

●Simple preset selection ensures consistent high-quality laser welds and cleaning

●Presets include wobble welding function to accommodate wider seams and for parts with poor fit-up

●Operators can instantly switch between presets to process multiple material-thickness combinations

●Advanced operators can customize presets, save for future use and can be used by novice operators to produce the same results

●Presets include wobble welding function to accommodate wider seams and for parts with poor fit-up

●Operators can instantly switch between presets to process multiple material-thickness combinations

●Advanced operators can customize presets, save for future use and can be used by novice operators to produce the same results

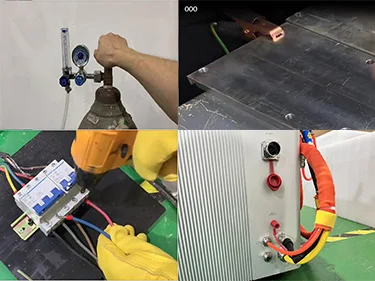

LightWELD is Fast & Easy to Set Up

●Ergonomic, compact and proven to be the most comfortable and easy to use laser gun with built-in wobble welding functionality.

●2-step trigger and part contact sensor enhance operator safety

●Purpose-built nozzle tips for various weld joint types and pre and post weld cleaning applications

●A single cable from the unit delivers laser power, gas and control connections to the gun

●2-step trigger and part contact sensor enhance operator safety

●Purpose-built nozzle tips for various weld joint types and pre and post weld cleaning applications

●A single cable from the unit delivers laser power, gas and control connections to the gun

Fast and Easy Setup

●Clearly labeled rear connections make getting started fast and easy

●Simply plug in power cord and gas connection, attach clamp to work surface, and the system is ready to go.

●Laser power, gas, and gun control are delivered through a single cable.

●An ethernet computer connection provides access to advanced parameter settings to fine tune and save process parameters.

●Simply plug in power cord and gas connection, attach clamp to work surface, and the system is ready to go.

●Laser power, gas, and gun control are delivered through a single cable.

●An ethernet computer connection provides access to advanced parameter settings to fine tune and save process parameters.

Optional Wire Feeding Package

● Wire welding capability extends laser welding applications to poorly fit-up parts

●Used for low carbon steel, stainless steel, aluminum and non-ferrous metals and alloys

●Wire feed speed range 40 – 600 cm/min (15 - 230 ipm)

●Wire diameter capacity 0.8 to 1.6 mm ( 0.035''- 0.063'')

●Wire feed tips: 0.8mm, 0.9mm, 1.2mm, 1.6mm

●Used for low carbon steel, stainless steel, aluminum and non-ferrous metals and alloys

●Wire feed speed range 40 – 600 cm/min (15 - 230 ipm)

●Wire diameter capacity 0.8 to 1.6 mm ( 0.035''- 0.063'')

●Wire feed tips: 0.8mm, 0.9mm, 1.2mm, 1.6mm

Handheld Laser Welding & Cleaning Systems

Easy to Learn

Built-in factory presets for welding and cleaning reduce learning curves, new welders can be trained within hour and experienced welders realize an immediate increase to productivity

Highly Productive

High-speed welding that is 4X faster than TIG, with simple material preparation and minimal post-finishing, plus wobble welding and wire feed options for consistent high-quality results

Highly Capable

Easily weld and clean thick, thin and reflective metals with low heat input from < .040" (1.0mm) up to 1/4" (6.35mm) with minimal part distortion, improved visual appearance and increased overall part quality

Built-in factory presets for welding and cleaning reduce learning curves, new welders can be trained within hour and experienced welders realize an immediate increase to productivity

Highly Productive

High-speed welding that is 4X faster than TIG, with simple material preparation and minimal post-finishing, plus wobble welding and wire feed options for consistent high-quality results

Highly Capable

Easily weld and clean thick, thin and reflective metals with low heat input from < .040" (1.0mm) up to 1/4" (6.35mm) with minimal part distortion, improved visual appearance and increased overall part quality

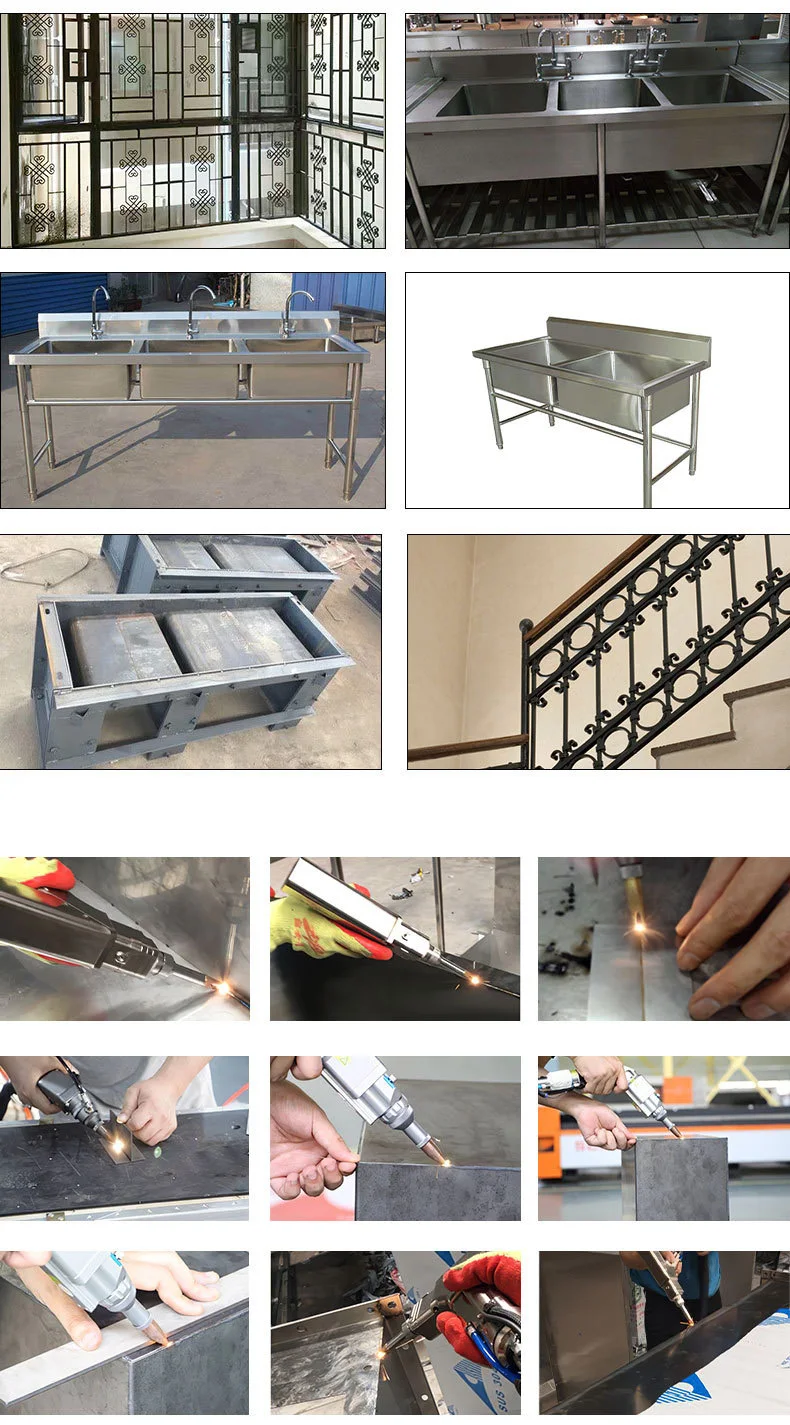

Cutting finished products show

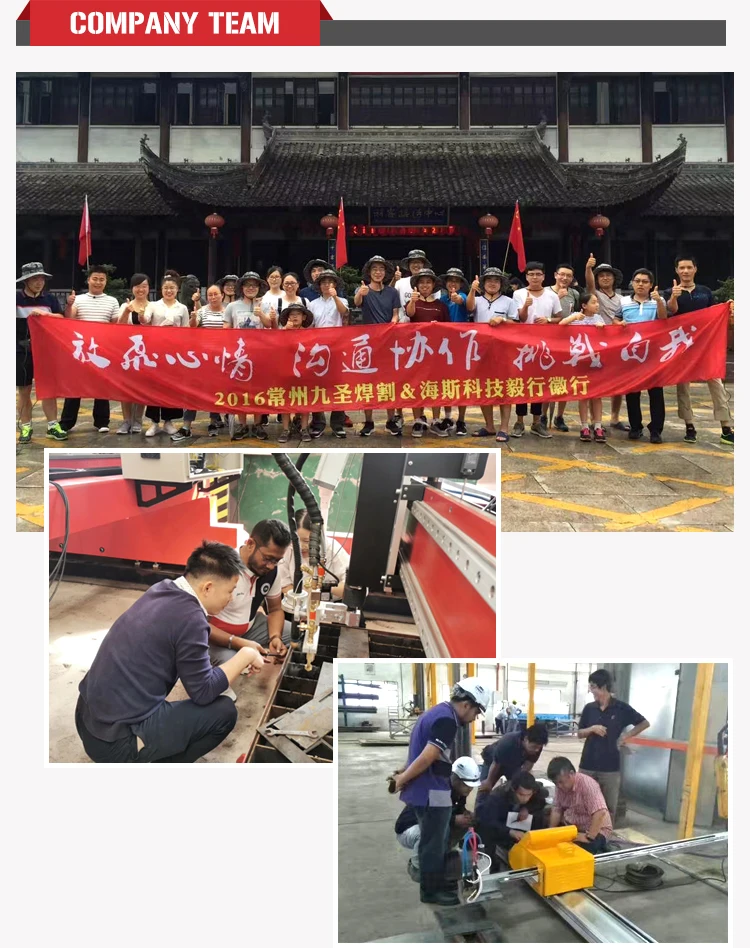

Company Profile

Changzhou Heavth Science & Technology Co , Ltd . was established in 2006 . We are located in Changzhou , which is the key city of Jiangsu province near to Shanghai .

We are supplying Laser CNC cutting machine , Portable CNC cutting machine , Gantry CNC cutting machine , CNC Pipe/tube cutting machine and other welding & cutting equipment . we have strong research and development ability . For now , we are supplying 6 series and over 30 kinds of products . We develop and design various types of CNC cutting machine and related accessories which are widely used in the large number of industrial circle .

Our company has strong technical force , advanced production equipment , detection means complete and excellent product quality .

Our products are sold to U.S.A , Canada , Australia , Europe , South East Asia , Africa etc , more than 100 countries and areas ,and supply OEM service for more than 20 manufactures . Heavth is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force .

We are supplying Laser CNC cutting machine , Portable CNC cutting machine , Gantry CNC cutting machine , CNC Pipe/tube cutting machine and other welding & cutting equipment . we have strong research and development ability . For now , we are supplying 6 series and over 30 kinds of products . We develop and design various types of CNC cutting machine and related accessories which are widely used in the large number of industrial circle .

Our company has strong technical force , advanced production equipment , detection means complete and excellent product quality .

Our products are sold to U.S.A , Canada , Australia , Europe , South East Asia , Africa etc , more than 100 countries and areas ,and supply OEM service for more than 20 manufactures . Heavth is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with an irresistible force .

Exhibitions & Feedback

Product packaging

Shipping&Payment

Share