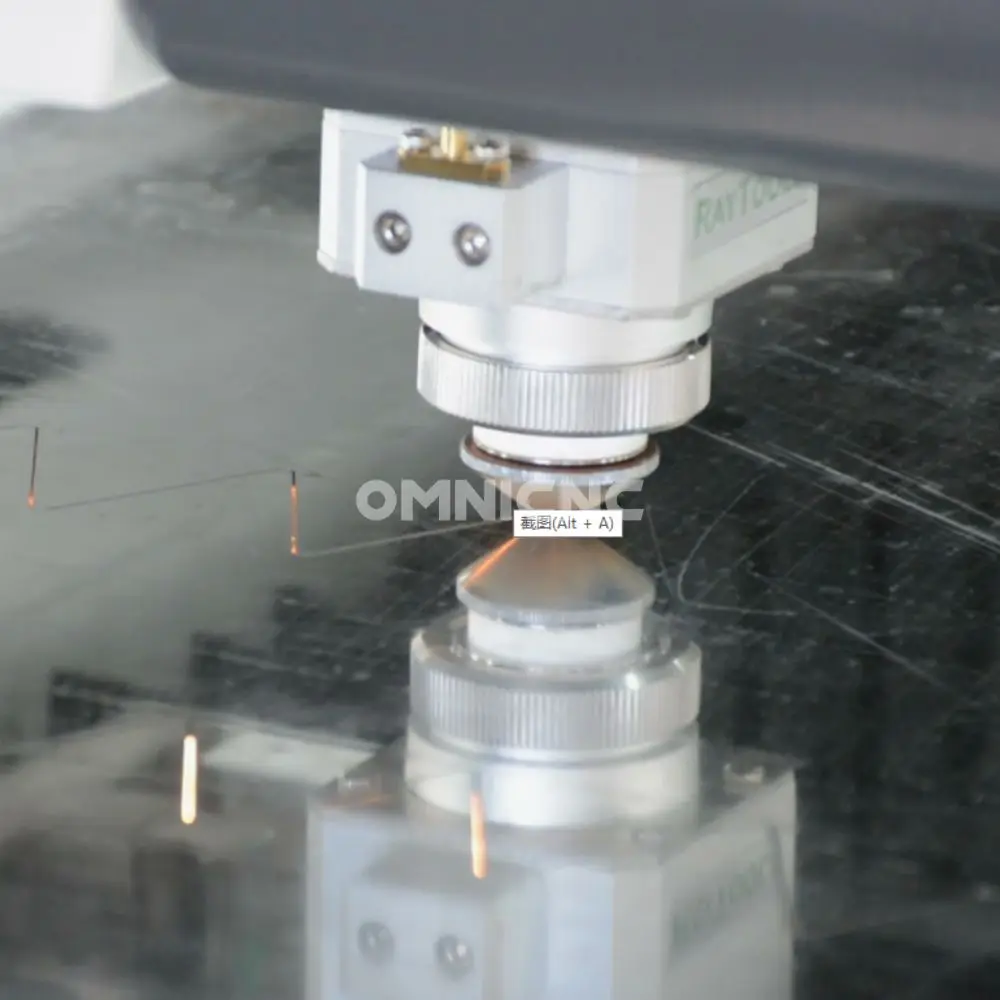

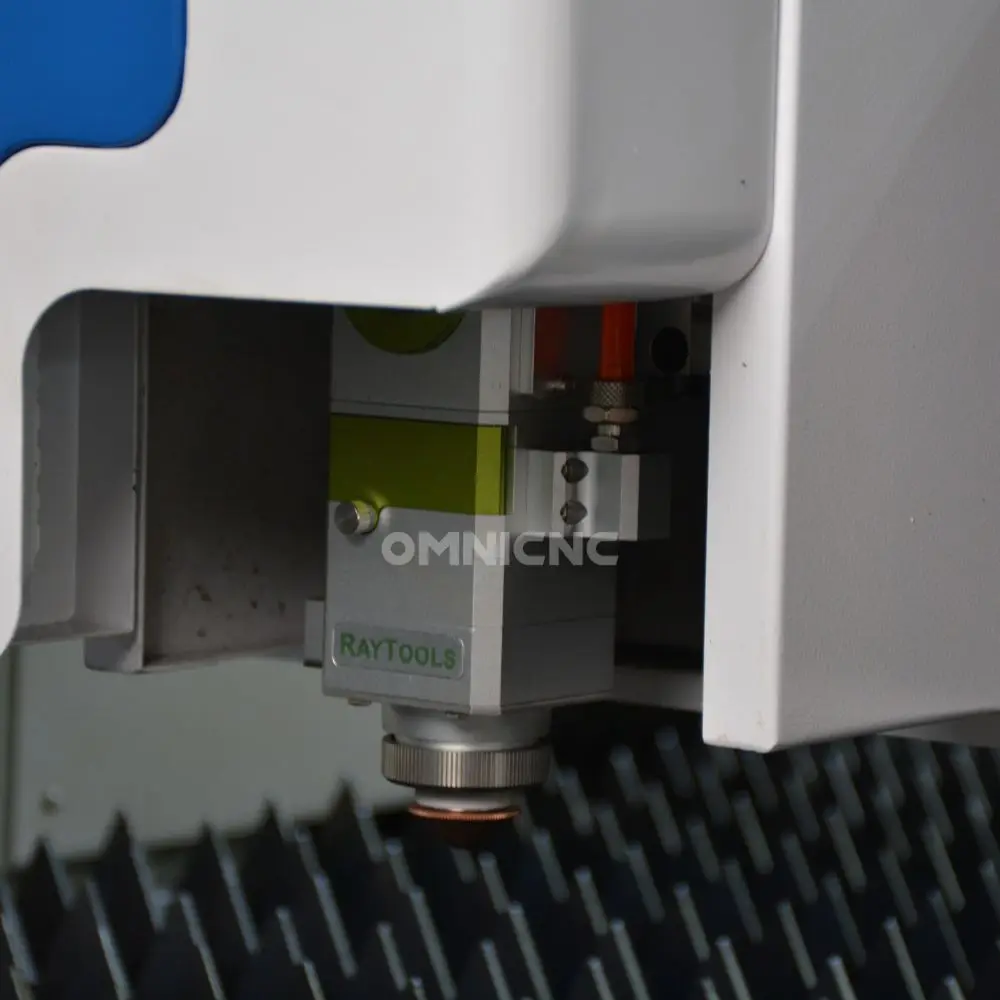

* This refers to the compatibility of the machine with various high-quality fiber laser cutting heads, like those manufactured by

Raytools, known for their reliability and performance.

1

/

of

0

007TECH

US$9999 Metal Fiber Laser Cutting Machine

US$9999 Metal Fiber Laser Cutting Machine

Regular price

¥4,371.00 CNY

Regular price

¥72,827.00 CNY

Sale price

¥4,371.00 CNY

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Product Description

Machines in Field

Metalworking and Fabrication

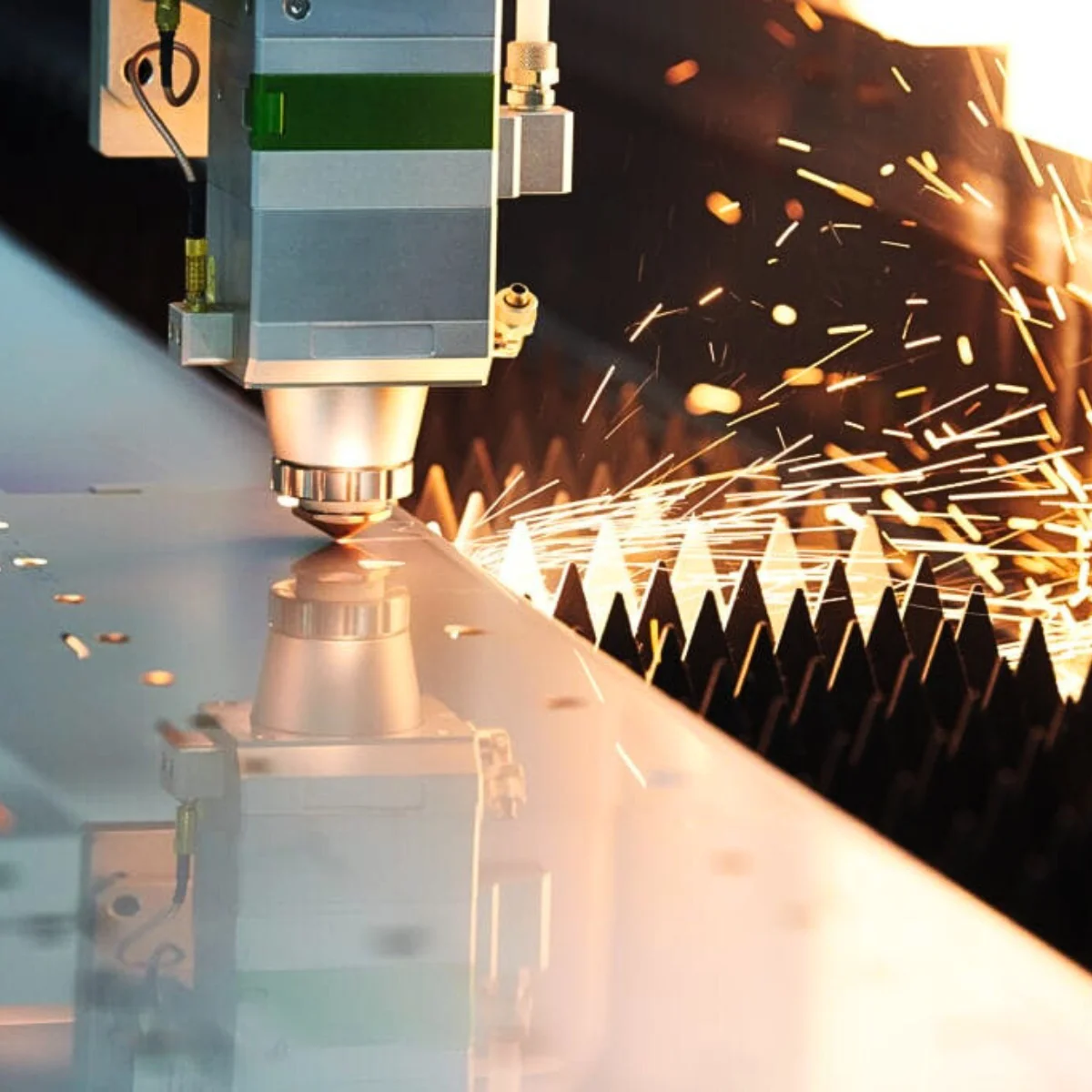

* Cutting sheet metal: Stainless steel, aluminum, mild steel, and other metals used in automotive parts, electronics enclosures, appliances, and onstruction materials.

* Creating intricate metal parts: Complex shapes and designs for components in various industries like aerospace, medical devices, and machinery.

* Pipe and tube cutting: Precise cuts for pipelines, automotive frames, and furniture.

* Creating intricate metal parts: Complex shapes and designs for components in various industries like aerospace, medical devices, and machinery.

* Pipe and tube cutting: Precise cuts for pipelines, automotive frames, and furniture.

AEROSPACE

* Producing high-precision parts: Creating components for aircraft, spacecraft, and satellites with strict dimensional tolerances.

* Working with lightweight materials: Cutting and shaping lightweight alloys like titanium and aluminum for weight reduction in aircraft.

* Maintaining material integrity: Ensuring minimal heat distortion during cutting, crucial for aerospace components.

* Working with lightweight materials: Cutting and shaping lightweight alloys like titanium and aluminum for weight reduction in aircraft.

* Maintaining material integrity: Ensuring minimal heat distortion during cutting, crucial for aerospace components.

Furniture & Appliance Manufacturing

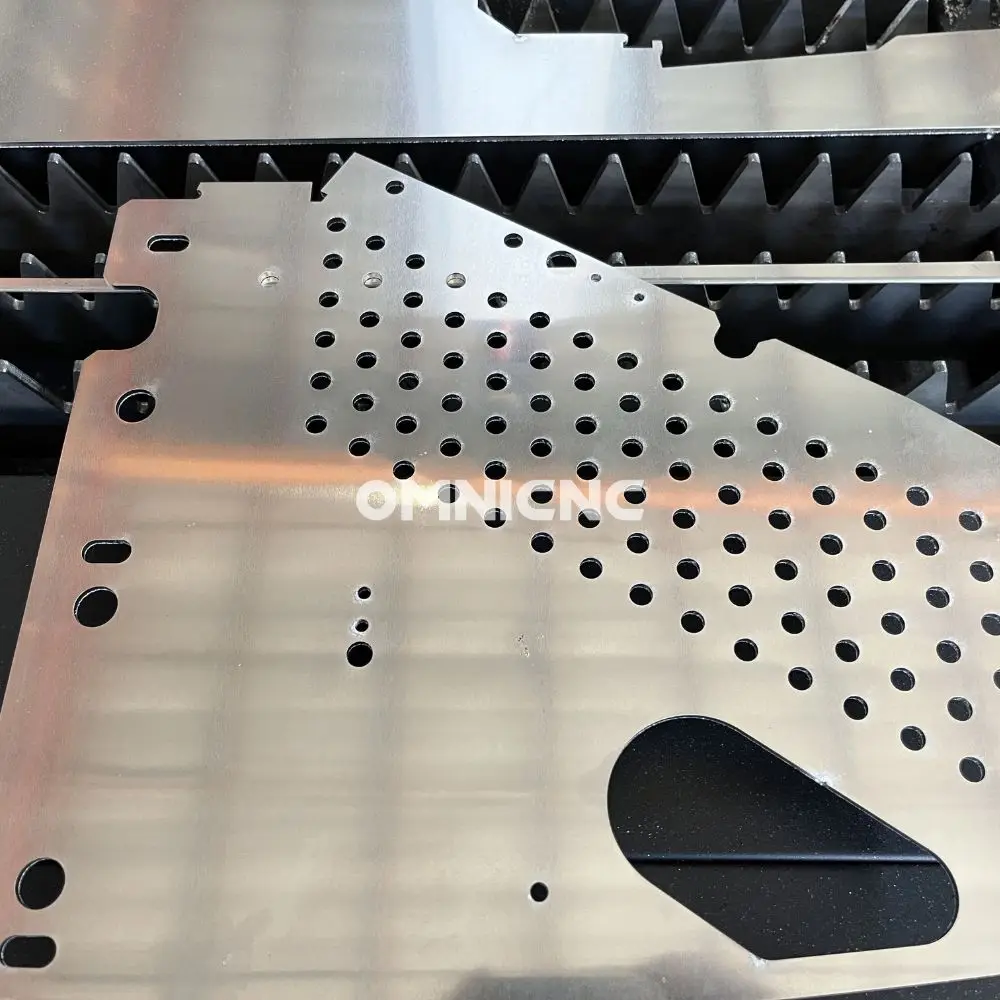

* Furniture manufacturing: * Precisely cutting intricate designs on wood, metal, and composite panels for furniture components like doors, drawers, and cabinet frames.

* Creating decorative elements like railings, scrolls, and filigree patterns.

* Appliance manufacturing: * Cutting and shaping sheet metal for appliance bodies, enclosures, and ducts.

* Creating precise openings and ventilation patterns.

* Creating decorative elements like railings, scrolls, and filigree patterns.

* Appliance manufacturing: * Cutting and shaping sheet metal for appliance bodies, enclosures, and ducts.

* Creating precise openings and ventilation patterns.

AUTOMOTIVE

* Cutting car body parts: Precise cuts for doors, hoods, trunks, and other components.

* Manufacturing exhaust systems: Cutting and shaping pipes and components for exhaust systems.

* Creating lightweight components: Contributing to fuel efficiency by enabling the use of lighter materials.

* Manufacturing exhaust systems: Cutting and shaping pipes and components for exhaust systems.

* Creating lightweight components: Contributing to fuel efficiency by enabling the use of lighter materials.

ELECTRONICS

* Electronic components: Cutting and shaping various electronic components like resistors, capacitors, and connectors.

* Heat sinks: Creating complex heat dissipation designs for electronic devices.

* Heat sinks: Creating complex heat dissipation designs for electronic devices.

SINAGE

* Crafting eye-catching signage and displays: Highlighting the visual appeal of laser-cut advertising materials.

* Fabricating diverse advertising materials: Emphasizing the versatility of fiber lasers for various signage applications.

* Fabricating diverse advertising materials: Emphasizing the versatility of fiber lasers for various signage applications.

Materials It Handled

Aluminium & Its Alloy

Lightweight and strong, used in aerospace, electronics, and automotive industries.

Stainless Steel

High corrosion resistance makes it ideal for appliances, medical devices, and automotive parts.

Carbon Steel

Versatile and cost-effective, used in construction, machinery, and automotive applications.

Titanium

High strength-to-weight ratio, used in aerospace, medical implants, and sporting goods.

Copper and its Alloys

Excellent heat conductor, used in electronics, electrical components, and heat exchangers.

Nickel Alloy

High corrosion and heat resistance, employed in chemical processing, nuclear power, and oil & gas industries.

Products Description

1KW Qualified Fiber Laser Cutting Head with Auto Focus Function

COLD DRAWN EXTRUDED ALUMINUM BEAM:

* Strength and stability: Ensures the machine can handle the forces involved in the cutting process.

* Reduced weight: Contributes to faster movement and improved cutting dynamics.

* Reduced weight: Contributes to faster movement and improved cutting dynamics.

raycus /Max. power source

Compatibility with laser sources from various manufacturers, including Raycus, and the ability to accommodate different maximum power levels. The specific power source and its maximum capacity will significantly impact the cutting thickness and performance of the machine.

Solid Frame

* Welded and machined: The frame typically comprises welded sections for structural integrity and machined surfaces for precise alignment of critical components. The combination ensures robustness and optimal alignment for accurate cutting results.

CNC control system FSCUT

Simple workflow, enhanced user experience.

Intuitive interface, wide compatibility, smooth operation.

One-click metal processing, design to cutting.

Intuitive interface, wide compatibility, smooth operation.

One-click metal processing, design to cutting.

Product Paramenters

item |

OMNI3015 US$9999 |

Application |

LASER CUTTING |

Applicable Material |

Metal |

Condition |

New |

Laser Type |

Fiber Laser |

Cutting Area |

1500mm*3000mm |

Cutting Speed |

0-60000mm/min |

Graphic Format Supported |

AI, PLT, DXF, Dst, Dwg, LAS, DXP, CDR |

Cutting Thickness |

0-4mm |

CNC or Not |

Yes |

Cooling Mode |

WATER COOLING |

Control Software |

FSCUT |

Place of Origin |

China |

Shandong |

|

Brand Name |

OMNI |

Laser Source Brand |

MAX |

Laser Head Brand |

Raytools |

Servo Motor Brand |

Leadshine |

Guiderail Brand |

HIWIN |

Control System Brand |

MAX |

Weight (KG) |

1000KG |

Key Selling Points |

Multifunctional |

Optical Lens Brand |

II-VI |

Warranty |

1 Year |

Applicable Industries |

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works , Energy & Mining, Advertising Company |

Machinery Test Report |

Provided |

Video outgoing-inspection |

Provided |

Warranty of core components |

1 Year |

Core Components |

Motor, Pump, laser tube |

Mode of Operation |

continuous wave |

Configuration |

3-axis |

Products handled |

Sheet Metal |

Feature |

Water-cooled |

After-sales Service Provided |

Engineers available to service machinery overseas |

Why Choose OMNI

Built to Last

Durable construction & premium components ensure reliable performance & longevity.

Global support network for worry-free operation.

Global support network for worry-free operation.

Precision Powerhouse

Industry-leading Yaskawa servos & HIWIN rails deliver unmatched accuracy, speed, & stability for demanding projects.

Material Mastery

Conquer diverse materials, from wood & composites to aluminum & more (check model capabilities) with versatile cutting capability.

CONTACT US

FAQ

* Q: What materials can the Omni fiber laser cutting machine cut? * A: The Omni fiber laser cutting machine primarily cuts

various metals, including stainless steel, carbon steel, aluminum, and copper, with specific thicknesses depending on the model and power source.

* Q: What are the benefits of using a fiber laser cutting machine compared to other cutting methods? * A: Advantages include high speed, precision, clean cuts, minimal heat-affected zone, and versatility for various metal cutting applications.

* Q: What safety features does the Omni fiber laser cutting machine have? * A: Common safety features include interlocks, emergency stops, and laser radiation protection to ensure operator safety.

various metals, including stainless steel, carbon steel, aluminum, and copper, with specific thicknesses depending on the model and power source.

* Q: What are the benefits of using a fiber laser cutting machine compared to other cutting methods? * A: Advantages include high speed, precision, clean cuts, minimal heat-affected zone, and versatility for various metal cutting applications.

* Q: What safety features does the Omni fiber laser cutting machine have? * A: Common safety features include interlocks, emergency stops, and laser radiation protection to ensure operator safety.

* Q: What is the working area of the Omni fiber laser cutting machine? * A: This depends on the specific model, but typical

working areas range from 3000 mm x 1500 mm (118.11 in x 59.06 in) to larger options.

* Q: What is the maximum cutting thickness of the Omni fiber laser cutting machine? * A: The maximum cutting thickness varies depending on the model, material type, and laser power source. It typically ranges from 1 mm to 20 mm or even higher in some models.

* Q: What type of laser source does the Omni fiber laser cutting machine use? * A: The specific source may vary depending on the model, but it often supports compatibility with various manufacturers like Raycus and offers different maximum power levels.

working areas range from 3000 mm x 1500 mm (118.11 in x 59.06 in) to larger options.

* Q: What is the maximum cutting thickness of the Omni fiber laser cutting machine? * A: The maximum cutting thickness varies depending on the model, material type, and laser power source. It typically ranges from 1 mm to 20 mm or even higher in some models.

* Q: What type of laser source does the Omni fiber laser cutting machine use? * A: The specific source may vary depending on the model, but it often supports compatibility with various manufacturers like Raycus and offers different maximum power levels.

* Q: What software does the Omni fiber laser cutting machine use? * A: The specific control system and software may vary depending on the model. Some options include FSCUT and others.

* Q: Does the Omni offer software integration for design and preparation? * A: Some models may integrate CAD, Nesting, and CAM functionalities into a single platform, allowing users to design, nest, and generate cutting paths within the same software.

* Q: Does the Omni offer software integration for design and preparation? * A: Some models may integrate CAD, Nesting, and CAM functionalities into a single platform, allowing users to design, nest, and generate cutting paths within the same software.

* Q: Does Omni offer after-sales support and training? * A: After-sales support and training availability may vary. Contact us confirm their specific offerings.