Machine lntroduction:

Laser welding a high efficient precision welding methodwhich is in the use of high energy density laser beam as aheat source .

Laser radiates and heats the workpiece surface, Thesurface heat diffuses to the inside through heat conduction,Then the laser makes the workpiece meltingand form the specific welding pool by controlling the laserpulse width, energy, peak power and repetition frequency.Due to its unique advantages, it has been successfullyapplied to the precise welding for micro parts and smallparts.

Laser welding is fusing welding technology, laser welderputs laser beam as the energy source, and make it impacton the weldment joints to realize welding .

1

/

de

0

007TECH

High Quality Aluminum Laser Welding Machine With Laser Joint

High Quality Aluminum Laser Welding Machine With Laser Joint

Preço normal

¥742.00 CNY

Preço normal

¥742.00 CNY

Preço de saldo

¥742.00 CNY

Preço unitário

/

por

Envio calculado na finalização da compra.

Não foi possível carregar a disponibilidade de recolha

Product Description

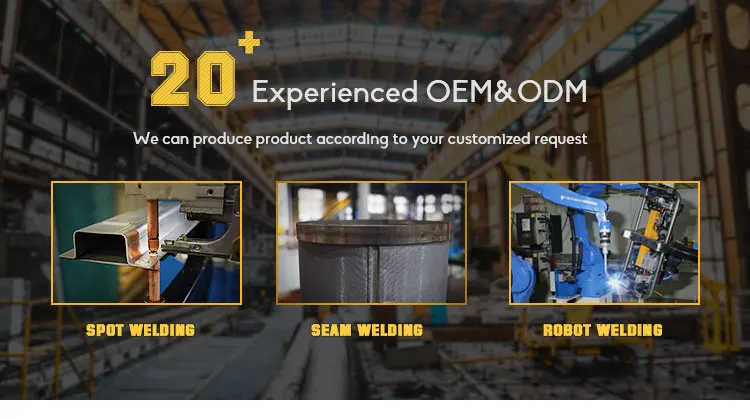

Support the proofing of welding products.Customized service: We can design and develop welding machines according to your requirements. We have many welding design cases, including automatic welding production lines. We are an efficient and capable OEM supplier.

Model |

TR-1000/TR-1500 |

Output optical power |

1000W/1500w |

Large pulse energy |

100J |

High peak power |

9.9kw |

Pulse width |

0-15ms |

Repetition frequency |

50-50,000HZ |

Spectroscopic methods |

Precision energy splitting or high speed time splitting |

Closed loop feedback control |

Arbitrary waveform rea-time control power negative feedback |

Energy fluctuation |

≤士3% |

Aiming mode |

Laser diode red light indication |

Numbers of optical fiber paths |

standard one light paths |

Cooling way |

Built-in water chiller |

Power consumption of equipment |

≤5kw |

Power requirements |

AC 220V+15%,50HZ/60HZ |

Size of host |

1360*660*1060mm |

1.The weld seam is smooth and beautiful, reducing the subsequent grinding process, saving time and welding operatorcost.

2. Wobble welding head compensates for the small disadvantage of laser welding spot, expands the tolerance randeof the machined pats and weld width, and obtains better weldformation.

3.The welding workpiece has no deformation, no welding, andthe welding is firm.

4.Laser welding consumes less material and has a long life.

5. Safer and more environmentally friendly.

6.The welding speed is 2-10 times faster than the traditionalwelding. One machine can save at least 2 welders a year.

7.The operation is simple, and it is possible to get on the jobwithout a job certificate and the beautiful product can bewelded without trainer.

Comparion of Argon Arc weldingand laser welding

Application:

1.Welding in thin stainless steelsheet, iron sheet, galvanizedsheet and other metal materials.can perfectly replace the

traditional argon arc welding, electric welding andother processes.

2.Handheld laser welding machine can be widely used incabinets, kitchens, staircases,elevators, racks, ovens,doorsand windows guardrail, distribution boxes, home andother industries complex andirregular welding process.

Welding machine and accessories introduction

Related Products

Company Introduction

TRINTFAR in 1995, Trintfar is a high-tech enterprise of automatic welding equipment integrating scientific research, development, manufacturing and sales. As a national high-tech enterprise, after more than 20 years of unremitting efforts,

TRINTFAR has many cutting-edge welding technology products, including medium frequency, high frequency inverter resistance welding machine, numerical control resistance welding, laser welding equipment, automobile welding production line, welding robot integrated system, high speed steel drum seam welding machine, etc.

It is not only used in major automobile manufacturing and parts manufacturing enterprises, but also in aerospace, home appliance manufacturing, high-speed rail, low-voltage electrical appliances and other industries. The innovative team, excellent product design, advanced technology and reliable quality have made the TRINTFAR brand a reputation as a "reliable partner" in the welding equipment market at home and abroad.