NaN

/

de

-Infinity

007TECH

Woodworking automatic kdt edge banding machine

Woodworking automatic kdt edge banding machine

Preço normal

¥4,394.00 CNY

Preço normal

¥21,969.00 CNY

Preço de saldo

¥4,394.00 CNY

Preço unitário

/

por

Envio calculado na finalização da compra.

Não foi possível carregar a disponibilidade de recolha

Product Description

ZD500 Automatic Edge Banding Machines edge bander

Thickness of banding |

0.4-3mm |

Width of banding |

10-60mm |

Thickness of workpiece |

10-60mm |

Heating power |

1.5kw |

Feeding motor power |

2.2kw |

Glue post motor |

0.37kw |

End trimming motor |

0.55*2 kw |

Fine trimming motor |

0.75*2 kw |

Polishing motor |

0.18*2 kw |

Feeding speed |

13m/min |

Air pressure |

0.7Mpa |

Workpiece length |

>=100mm |

N.W. |

1300kg |

Overall dimension |

3600*900*1500mm |

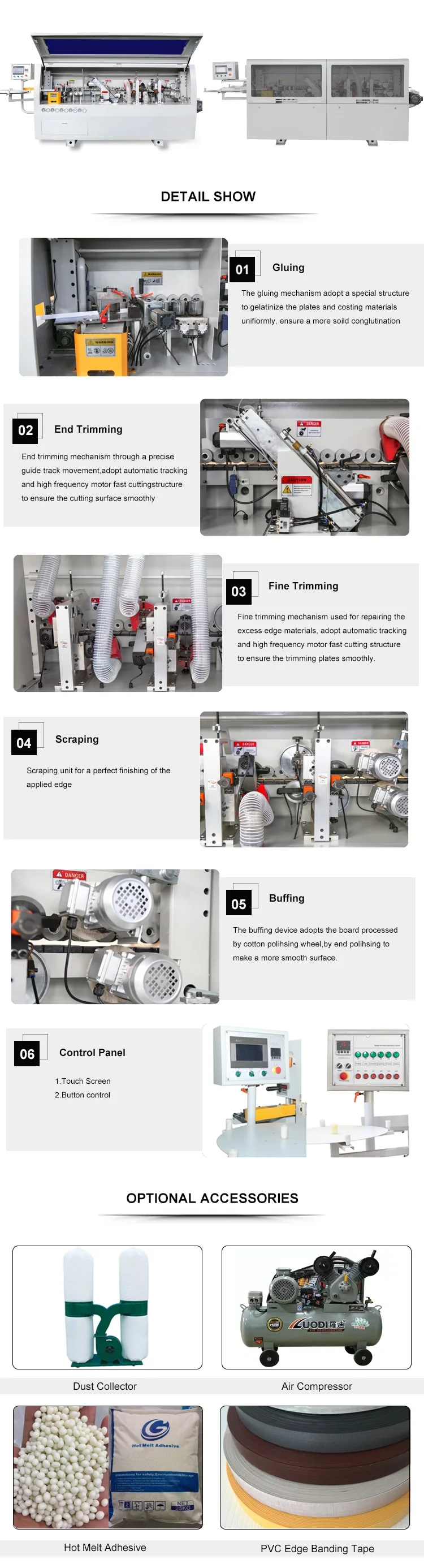

Detailed Images

1.Delta touch screen

2. Button control

Pre-milling equipment with double trimming blades works on the waved effect that is caused by panel saw.

ZD500/ZD600R does not include this unit,

ZD600P/ZD700/ZD800 with premilling.

Custom made is acceptable.

The gluing mechanism adopt a special structure to gelatinize the plates and costing material unifiormly, ensure a more solid conglutionation

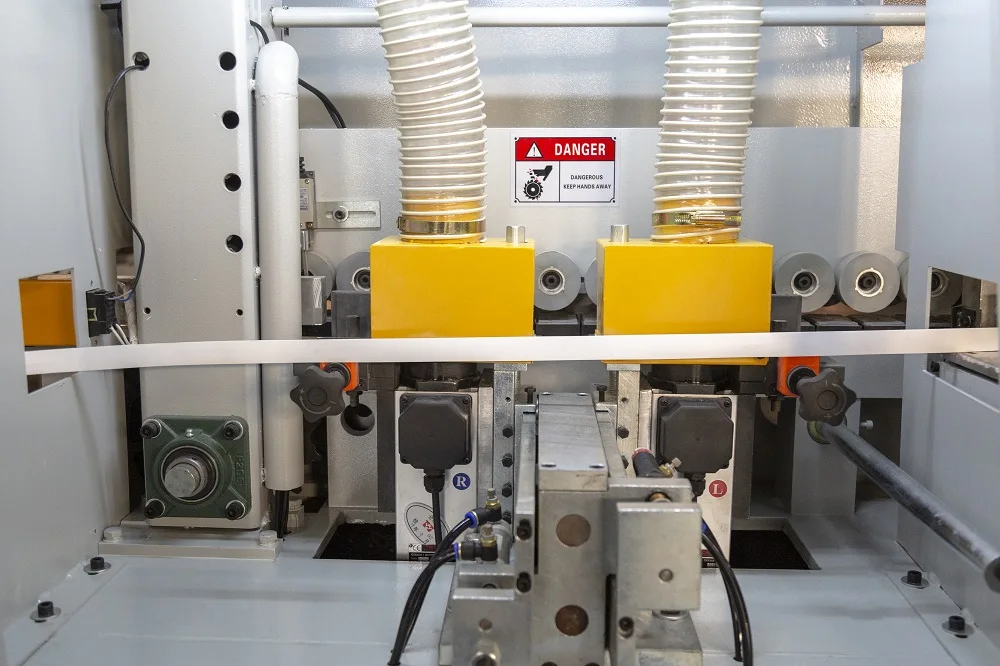

End trimming mechanism through a precise guide track movement, adopt automatic tracking and high frequency motor fast cutting structure to ensure the cutting surface smoothly.

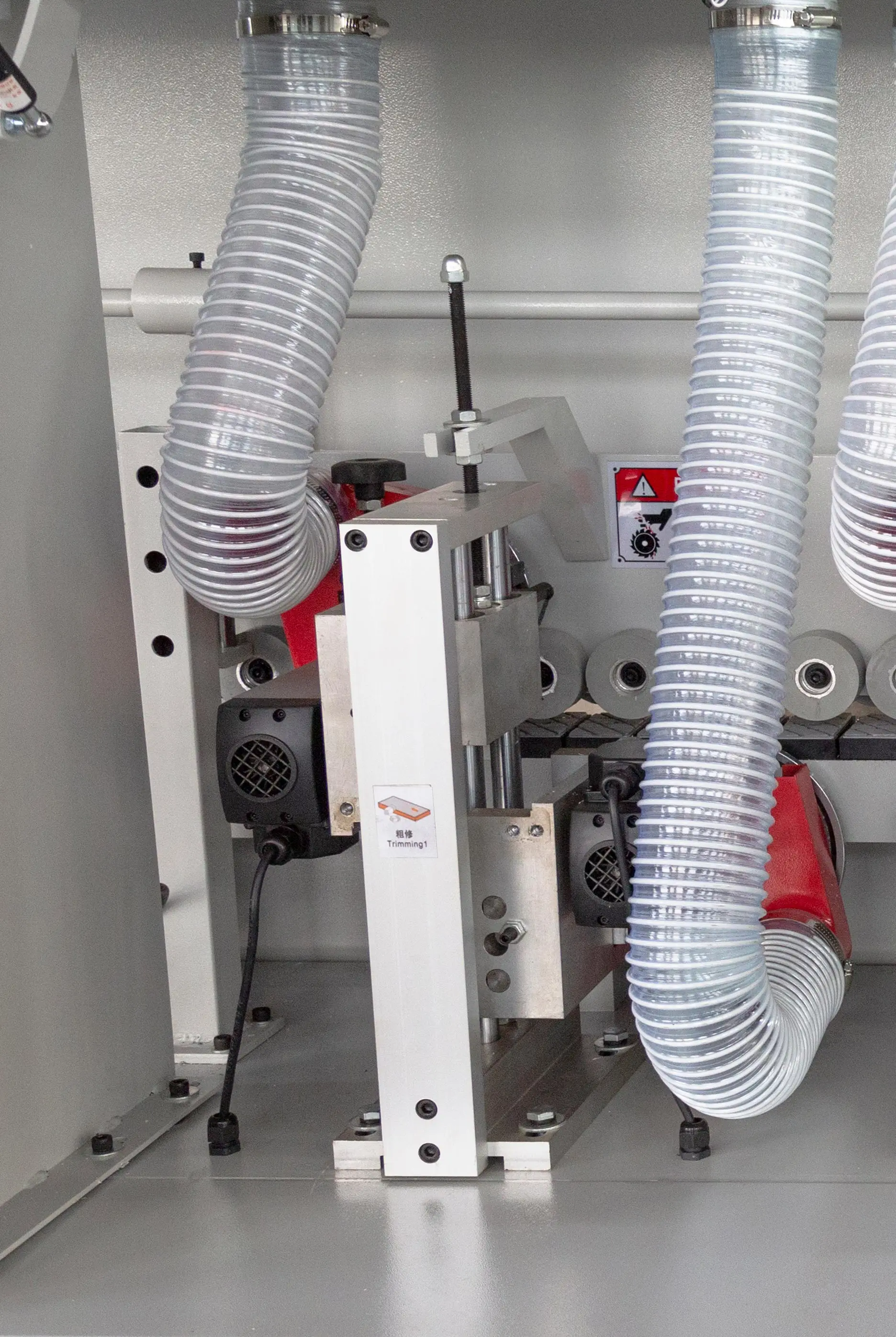

Rough trimming mechanism used for trimming the excess edge materials, adopt automatic tracking and high frequency motor fast cutting structure to ensure the trimming plates smoothly.

ZD600R/ZD700/ZD800 with this function

Custom made is acceptable.

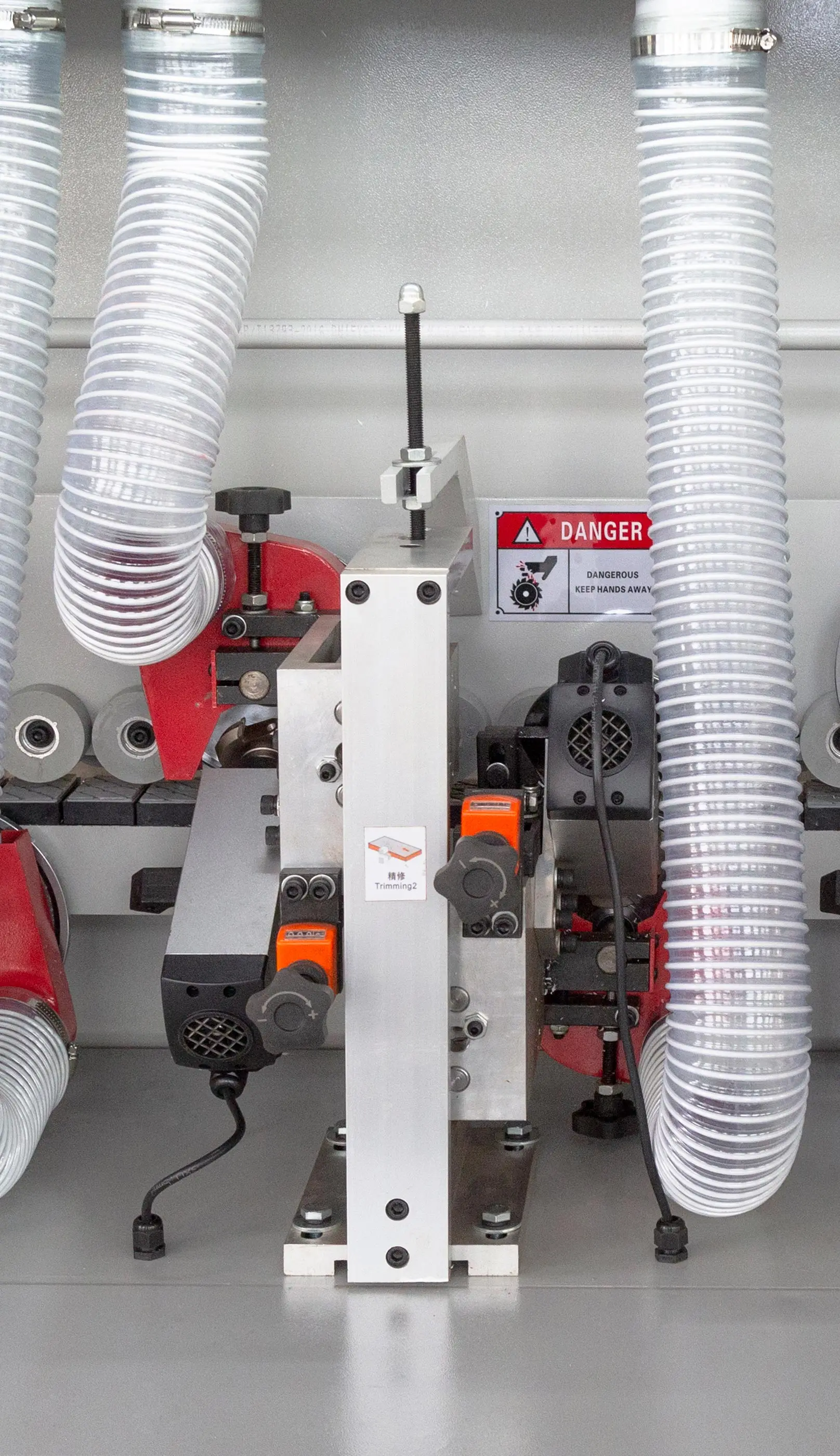

Fine trimming mechanism is to trim the R radian for the edge of band, to make it smooth and beautiful.

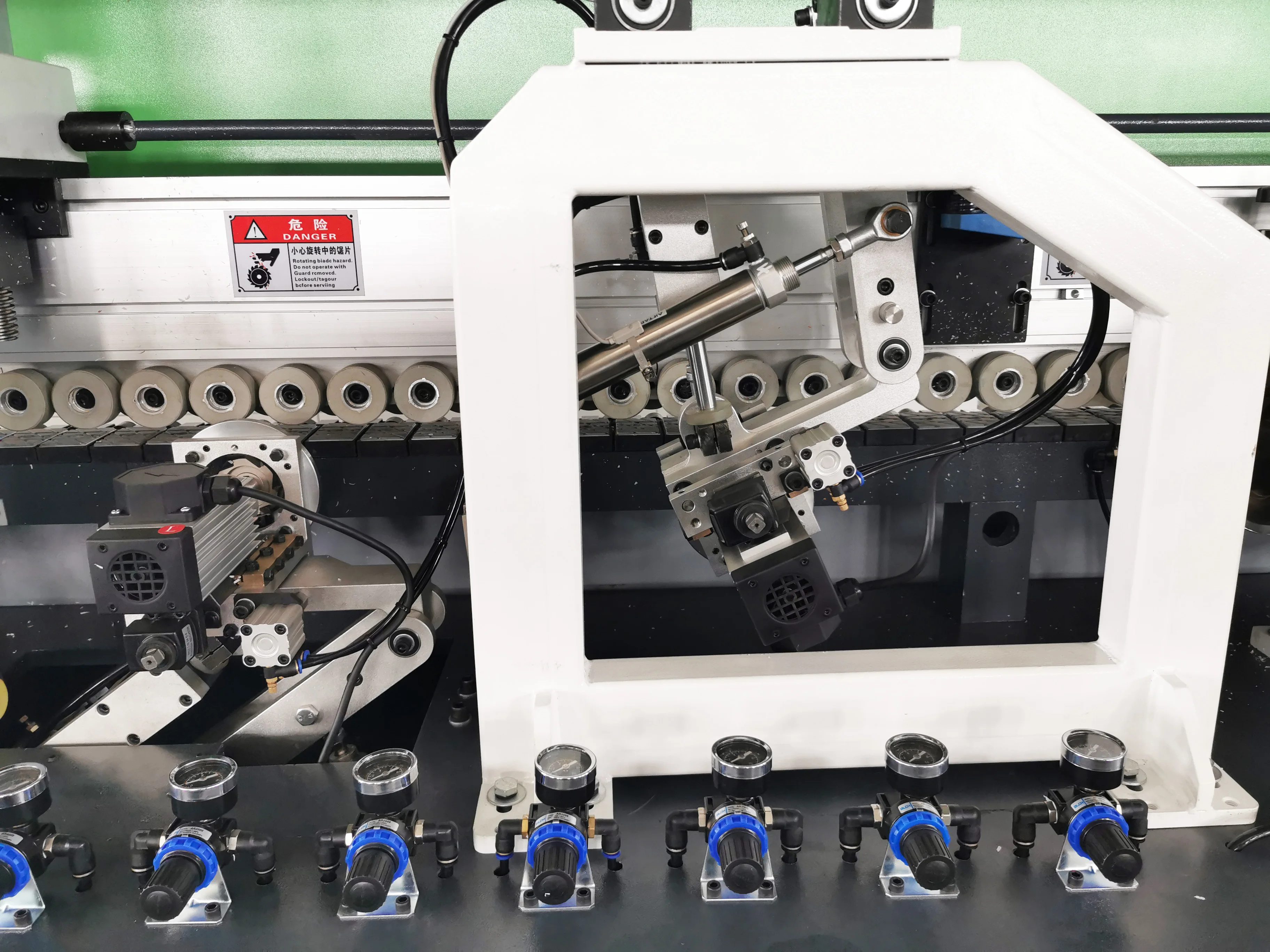

Corner rounding mechanism with two high precision tracking motor to make sure high tracking speed and high trimming speed.

ZD600C/ZD700C/ZD800 with this function

Custom made is acceptable.

Custom made is acceptable.

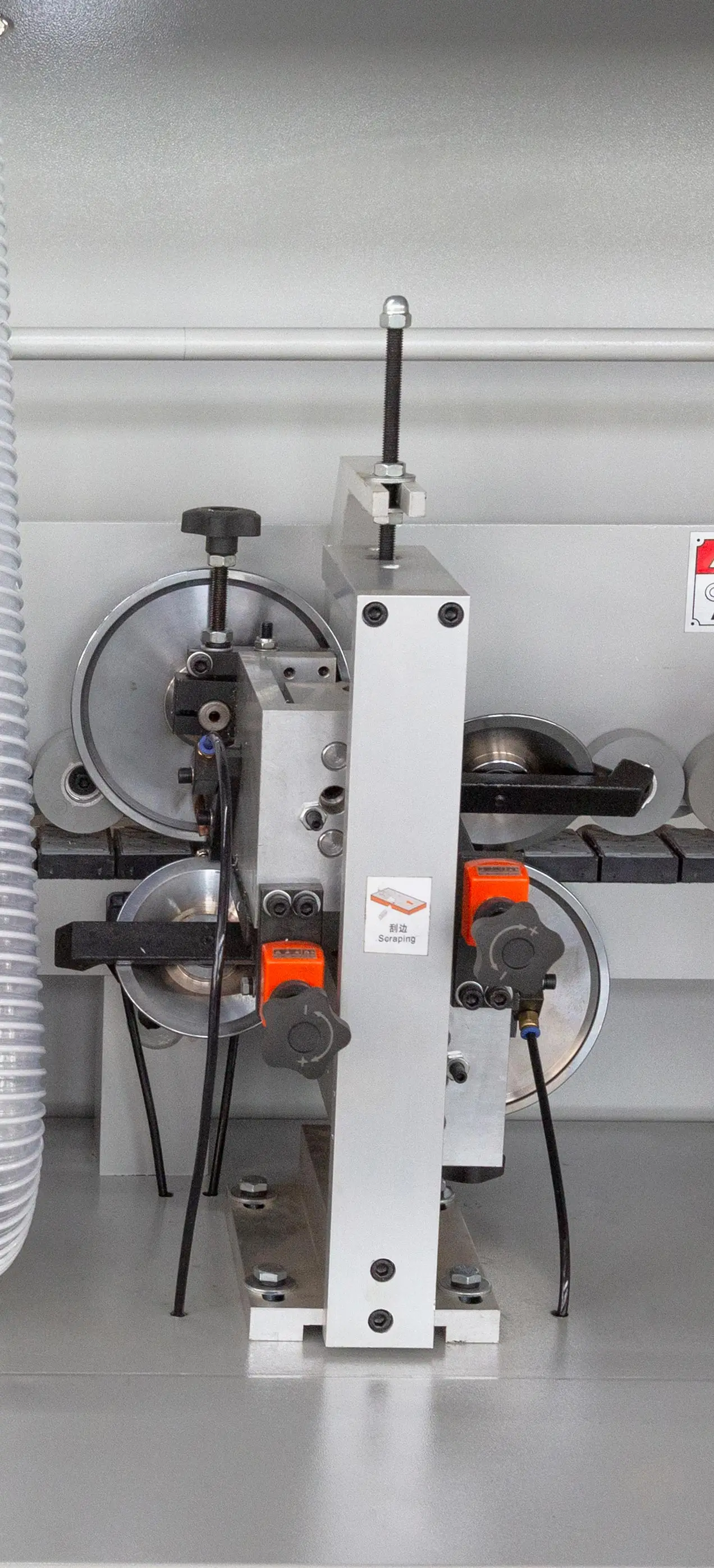

Scraping unit for a perfect finishing of the applied edge. Eliminate wavy lines in trimming.

The buffing device adopts the board processed by cotton polishing wheel, by end polishing to make a more clean and smooth surface.

OPTIONAL ACCESSORIES

edge banding machines edge bander

Dust collector

Different dust collectors (2.2kw, 3kw, 5.5kw, 7.5kw...) to choose

Air compressor

Provide air pressure for machines.

Hot melt glue

PUR, EVA hot melt glue.

Edge band tape

PVC, Veneer edge band tage

Related Products

Packing&Shipping

After Sales Service

Company Introduction

FAQ

Q1: Is it all right to make customer's own brand name?

A: Yes

Q2: Are you a manufacturer or trading company?

A: We have 20 years manufacturer and export experience.

Q3: What's the MOQ for your production?

A:1 set, and we are OEM, I will give you the competitive price better than market.

Q4: May I buy a sample?

A: Of course ,sample order is welcome.

Q5: How can I place a order?

A: Just give me your nice inquiry, I will do my best to assist you.

Q6: Packaging:

A: Standard plywood package or as your requirement.

Q7: What about the lead time for mass production?

A: Please send the details inquiry to us, such as the Item Number, Quantity for each item, Quality request, Logo, Payment Terms, Transport method, Discharge place etc. We will make the accurate quotation to you as soon as possible.